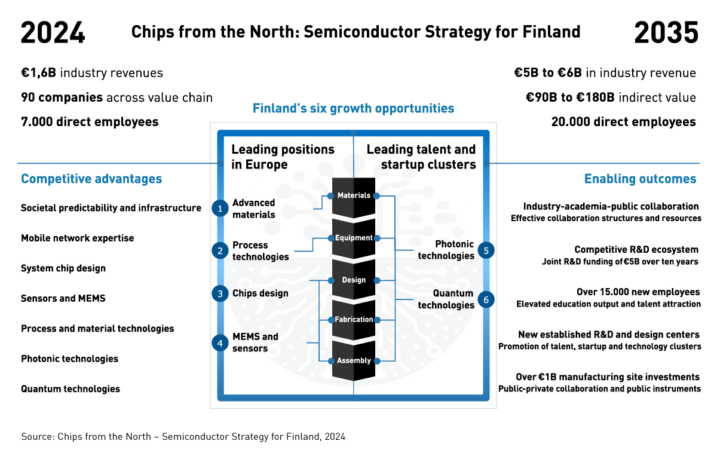

Membrane

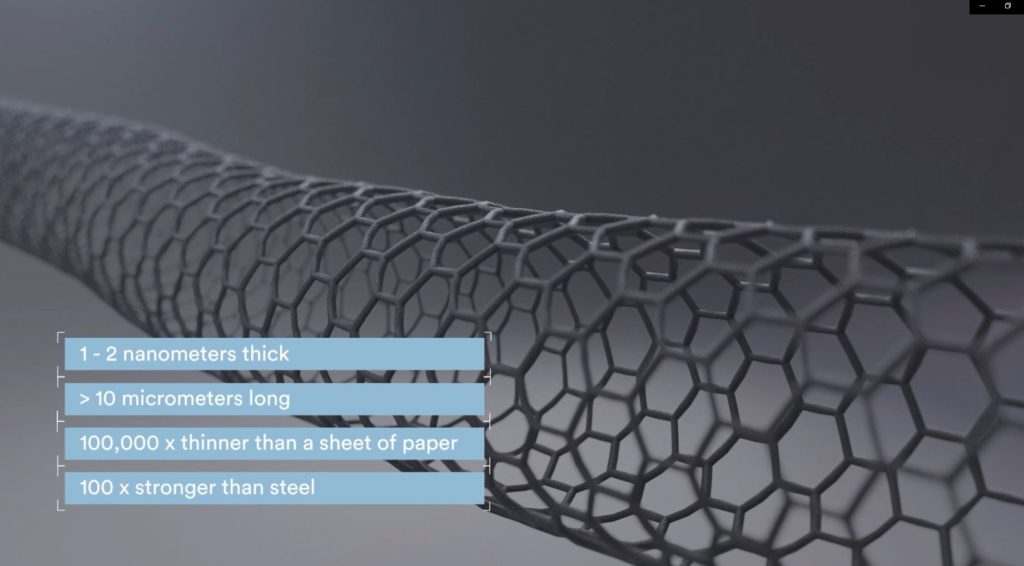

The world’s thinnest and strongest carbon nanotube membranes, tailorable for your exact needs. Applicable for high-power EUV lithography and X-Ray filter applications. Made of the most advanced carbon nanotubes, known for their exceptional purity and properties.

Canatu membranes: a versatile platform technology

Canatu membranes offer a versatile platform technology for EUV and optical filter applications. These membranes are created from Canatu carbon nanotubes, renowned for their exceptional purity and properties. Canatu CNTs are synthesized in a floating catalyst chemical vapor deposition (FC-CVD) reactor, and dry-deposited onto an open frame or a border. With more than a decade of experience in mass-producing CNTs, Canatu has highly-developed expertise in controlling this process, and tailoring CNTs and membranes to different needs. These membranes can be used e.g. as EUV pellicles, debris filters, electron blocking filter, and optical filters in EUV and X-Ray filter applications.

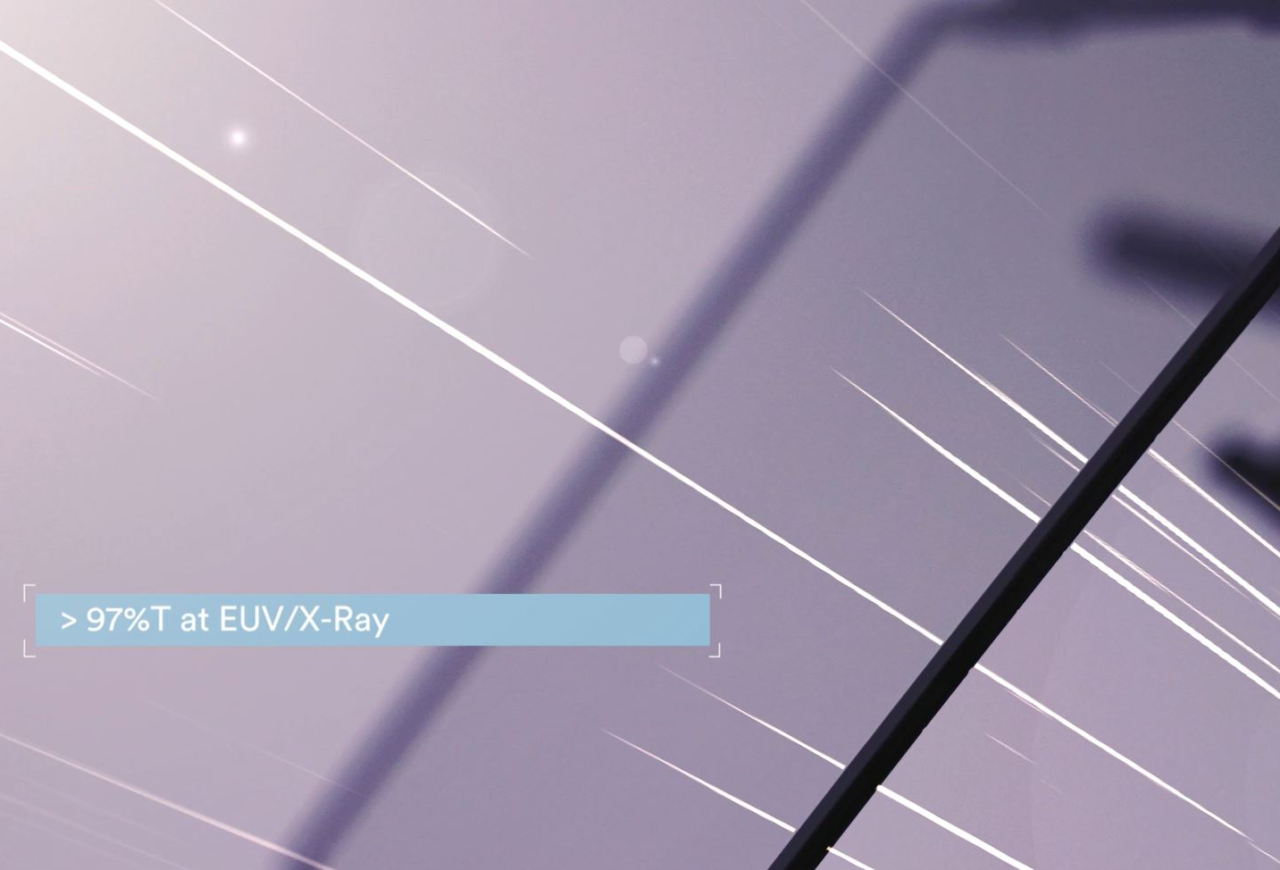

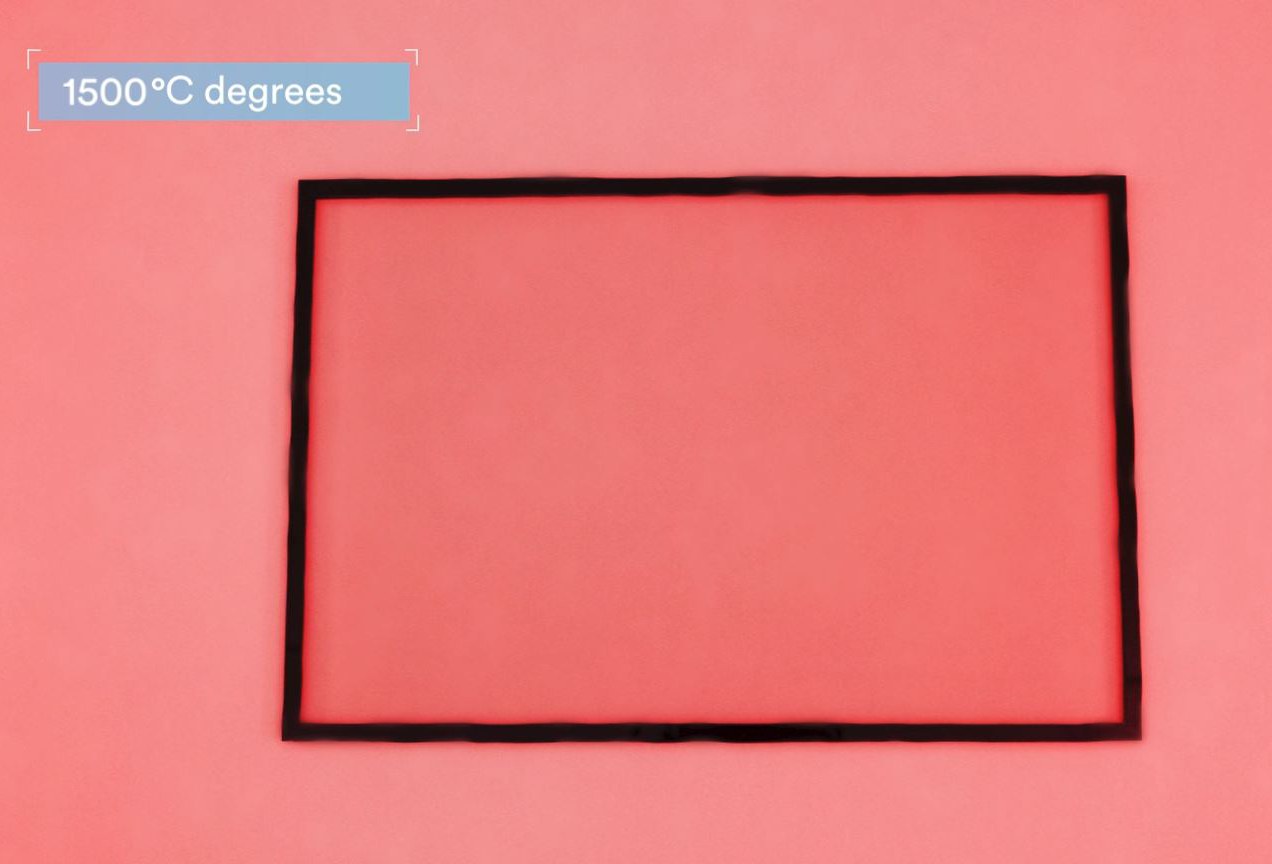

Canatu membranes are highly uniform and offer a distinctive set of properties, unequalled by any other material. Canatu membranes feature high EUV/X-Ray transmittance (>97%T), high mechanical strength, and exceptional thermal resistance (>1500°C), which makes them an attractive material for the extreme environments.

- Transparent: high EUV / X-Ray transmittance enhances throughput.

- Low flare: minimal scattering enables precise printing of tiny features without pattern distortion

- Robust: high heat resistance, chemical inertness, and high-pressure tolerance, ensuring durability in the next-gen scanners.

- Unique process: scalable and repeatable manufacturing process that preserves the pristine quality of carbon nanotubes.

- Tailored: tunable and functionalized to provide the exact properties necessary for each application.

High transmittance

Canatu’s ultra-thin CNT membranes offer >97%T at EUV / X-Ray and minimal flare (scattering). In EUV pellicle application, high transmittance means more EUV light passes through the pellicle and reaches the wafer, increasing throughput.

High heat resistivity

Canatu membranes have high heat resistivity and can endure exceptionally high temperatures without experiencing any degradation or structural damage. Our membranes can withstand temperatures as high as 1500°C. This level of heat resistivity far surpasses that of quartz, which breaks at 1200°C, and polyimide, which decomposes at temperatures below 520°C.

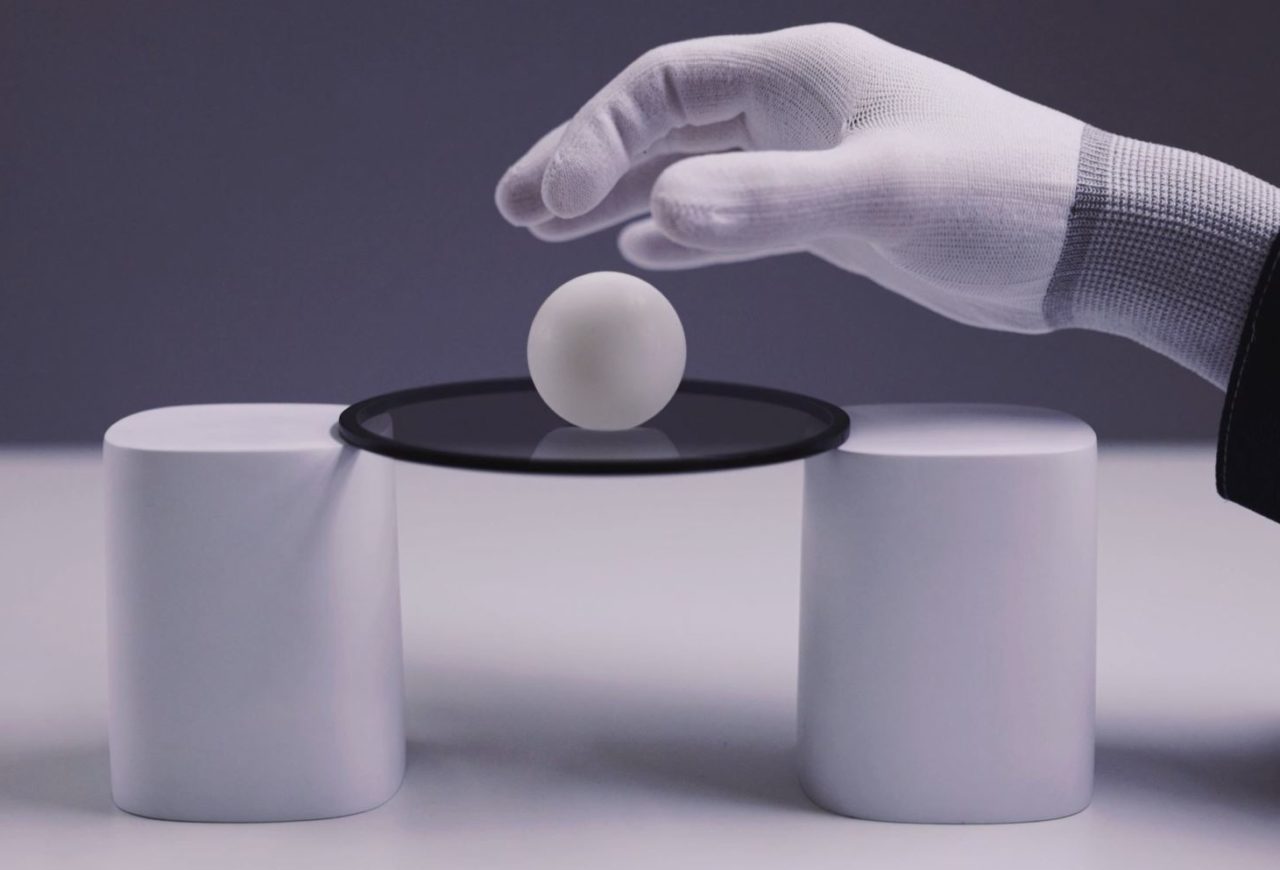

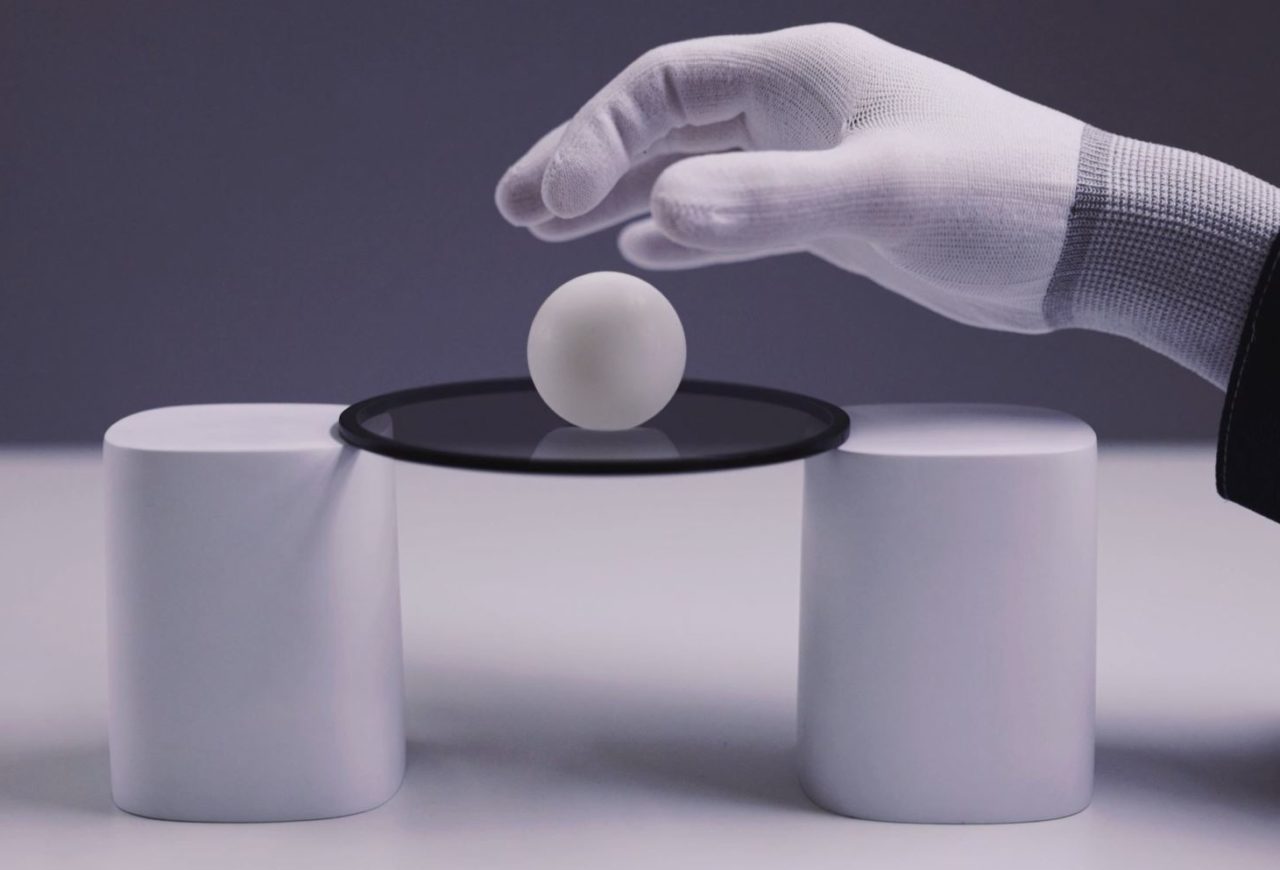

High mechanical strenght

The high tensile strength of 1-dimensional carbon nanotubes makes the 2-dimensional membranes very robust with highly versatile mechanical properties, even allowing for some stretching within the membrane to withstand unexpected mechanical loads without breaking or shattering. In EUV pellicle and debris filter applications, elasticity can help protect the system integrity in case of an accident or unforeseen consequences.

Download technical paper

Please download the most recent 2023 SPIE Photomask + EUVL Conference proceedings to gain deeper understanding of our versatile platform technology, unique CNT synthesis and direct dry deposition benefits, common tailoring, and potential uses for our carbon nanotube membranes.

Download technical paper

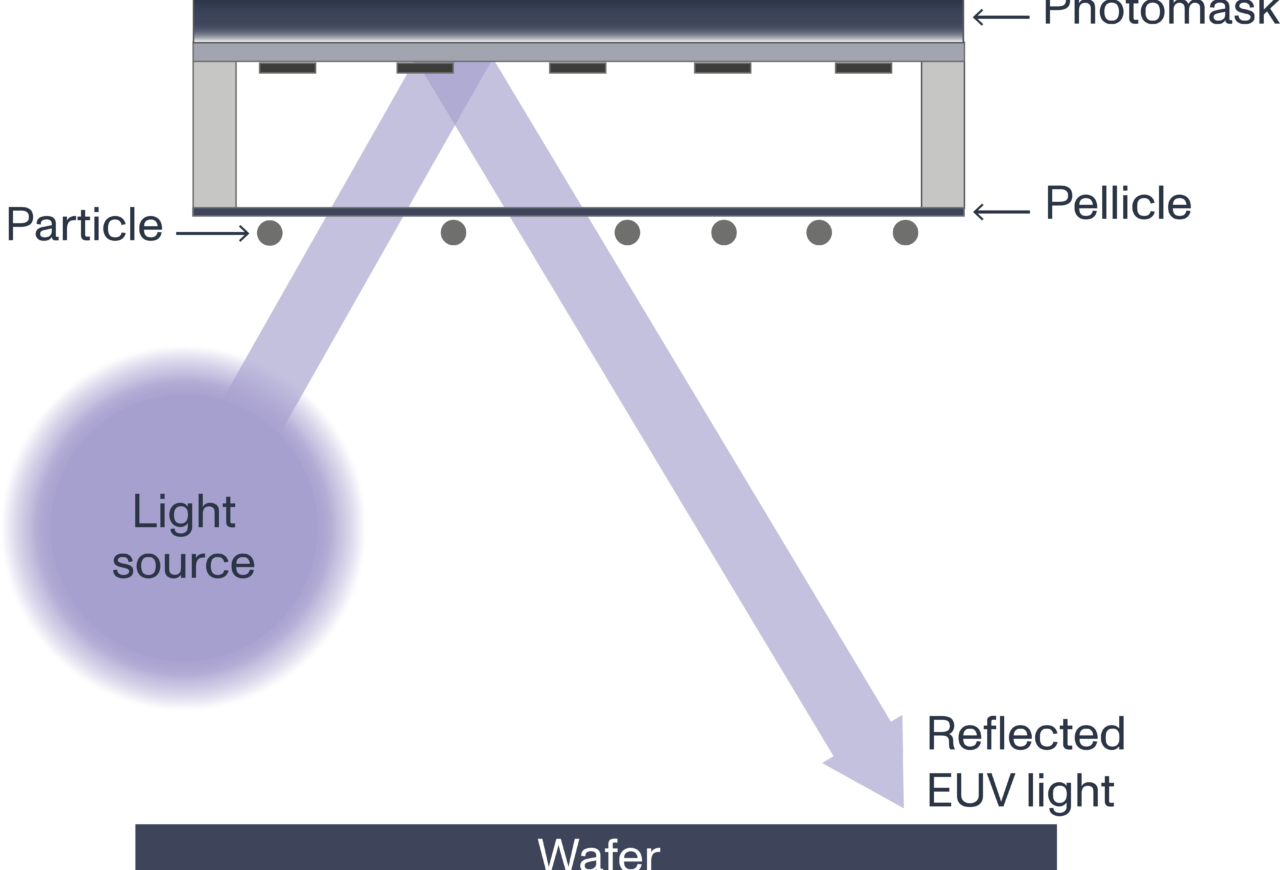

EUV pellicles

The next generation high-power extreme ultraviolet (EUV) lithography is bringing about increased power levels and reticle acceleration, boosting scanner efficiency. However, these improvements also come with challenges, including higher temperatures and mechanical stresses on the EUV pellicles. Carbon nanotubes have emerged as the most promising material for the EUV pellicles, thanks to their exceptional mechanical and thermal properties. EUV pellicles play a fundamental role in the EUV process in protecting the photomask from defects during chip production. EUV pellicles using Canatu CNT offer high EUV transmittance, exceptional durability in the vacuum chamber, along with high resistance to heat and pressure differences.

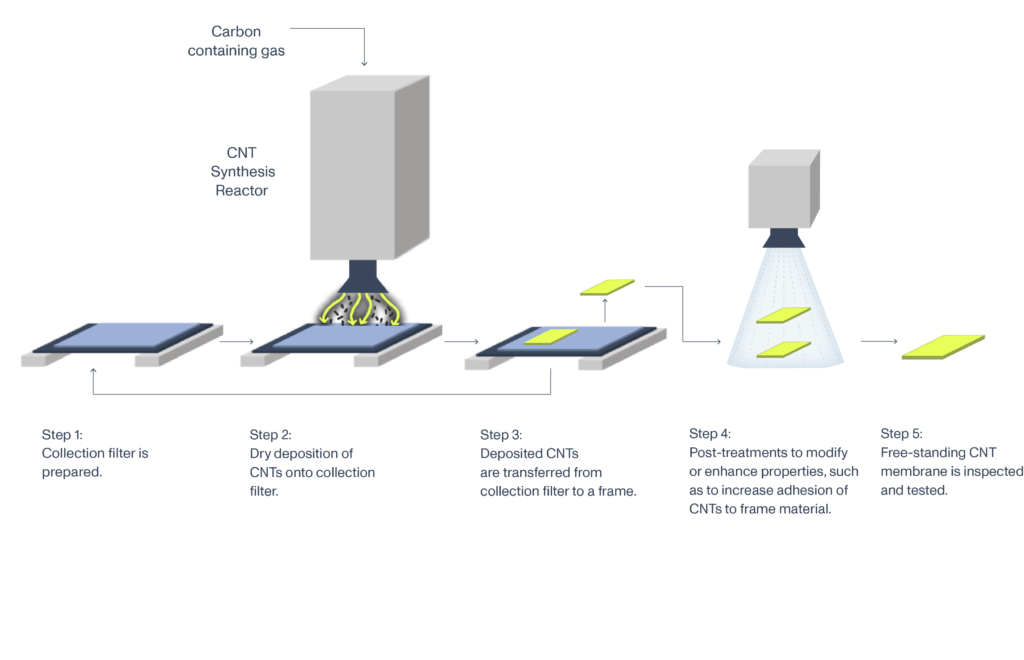

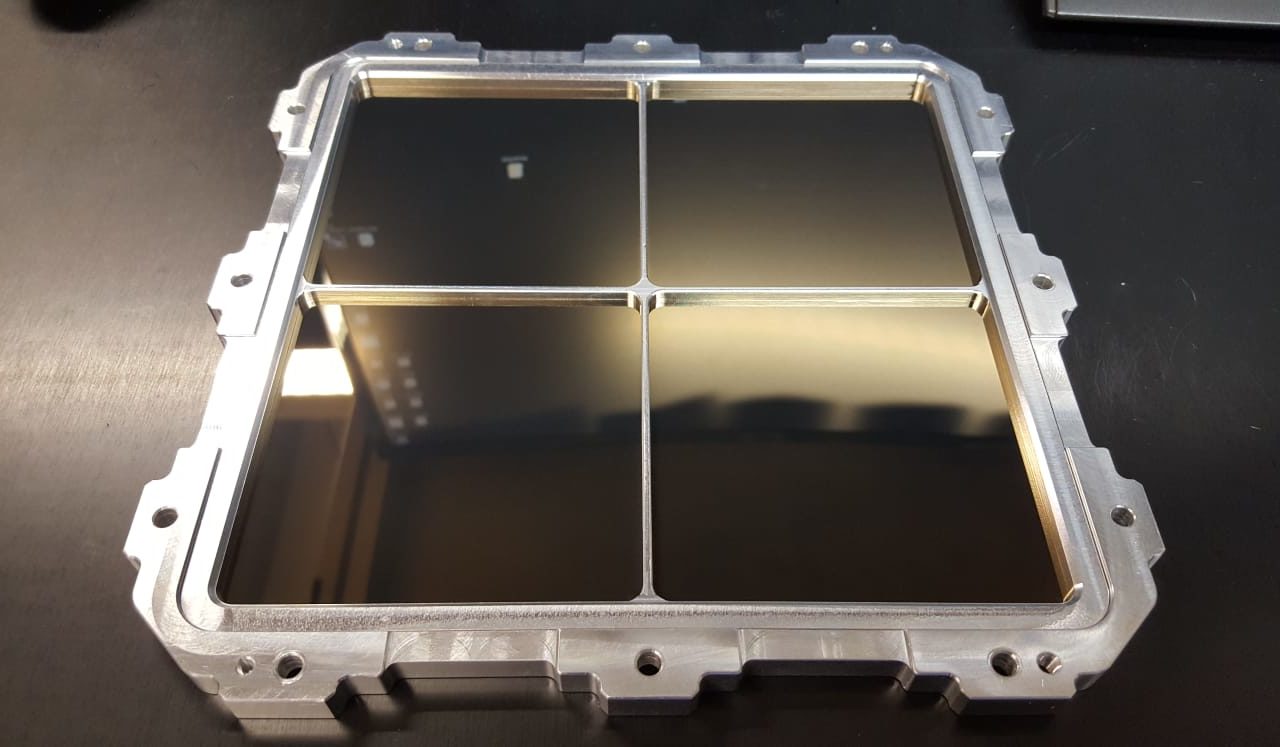

Membrane fabrication

Canatu carbon nanotubes are synthesized from gases in a floating catalyst chemical vapor deposition (FC-CVD) reactor. These CNTs are then collected onto a filter and dry deposited onto either an open frame or a border, creating a free-standing carbon nanotube membrane. This unique process yields high purity, strong, and uniform carbon nanotube membranes. Subsequently, these membranes undergo post-process steps to tailor membranes for application -specific requirements.

Canatu CNT is renowned for its high quality, purity, and remarkable properties. Our distinct expertise lies in having strong control over every aspect of the FC-CVD synthesis process, spanning from catalyst formation and activation to controlling temperature gradient, reagent gases, and the reactor design itself. With over a decade of experience in mass-producing CNTs, Canatu has highly developed expertise in tailoring our CNTs to meet the precise needs of various applications.

Membranes for your exact needs

Canatu CNT provides the versatility and reliability needed in highly engineered solutions. Both, the individual CNT properties, and the resulting membrane morphology can be tuned. For instance, we can modify the number of walls in individual CNTs, offering the flexibility to choose between single-walled CNTs (SWCNT) or multi-walled CNTs (MWCNT). Multi-walled CNTs can be beneficial when optimizing covalent coating processes. Additionally, tube diameter and chirality can also be adjusted independent of the wall count. The bundle size and the overall morphology of the membrane can be tuned during synthesis to optimize coating processes. This allows for controlling factors such as reducing the total surface area that needs to be coated, or limiting exposure to potentially harmful environments. Additionally, to fine-tune coating properties, the surface chemistry of CNTs can be pre-treated through targeted surface functionalization. If specific anisotropic properties, such as mechanical or electrical properties, are desired, the orientation of the CNT network can be precisely controlled. However, in EUV applications, where minimizing scattering and flare is essential, an isotropic orientation is preferred.

This versatile platform technology can be further enhanced through chemical functionalization and coating. For instance, coatings may serve purposes like filtering out deep ultraviolet (DUV) photons in optical filters, or creating a gas-seal and to separate gas compartments in EUV machinery. CNTs can be coated with any conventional PVD, ALD, or CVD coatings, as well as with a more novel electrochemical coating method. The inherent mechanisms of electrochemistry enable advantages such as enhanced conformality and thickness control in the coating process.

Finally, metal nanoparticles can be removed to ensure membrane purity. Metals are commonly used as catalysts in the CNT synthesis. Purification is often a fundamental necessity as any outgassing or ejection of material at high temperatures can damage other components within EUV machinery.

Canatu membranes are applicable for a variety of uses. Our CNT membranes are meticulously engineered to perform exceptionally well in the most demanding conditions, such as next-gen high power EUV lithography and optical filter applications. For instance, thicker and densely coated CNT membranes are inherently applicable for filtering debris from an EUV source, blocking DUV photons which could be detrimental to specific mirrors, detectors, or photoresists used in EUV machinery, and establishing an effective gas seal to control differential pressure. Canatu membranes are well-suited also for optical filter applications to block particles, electrons, and photons that fall outside the desired energy range.

Related videos

Contact

Send us a message

Related content

The next-gen EUV scanner will introduce high power levels of over 500W, enabling the next step in efficiency. Higher power levels and reticle acceleration cause high heat loads and mechanical stress on the EUV pellicles. Carbon nanotubes have emerged as the most promising material for EUV pellicles used in high power EUV scanners due to their mechanical and thermal properties. See article.

Semiconductors are all around us in every single electronic device we use. That is how they make an impact in our everyday. Progress in the semiconductor industry continues fast driven by Moore’s Law. Canatu CNT plays a role in enabling breakthroughs in the rapidly changing semiconductor industry. See more.

EUV pellicles made of Canatu CNT are critical enablers of high yield and throughput in high-volume semiconductor manufacturing, offering unique benefits that are unparalleled by other materials. See product.

Canatu CTO Ilkka Varjos presented free-standing CNT membrane platform technology at SPIE Photomask + EUVL 2021. His talk focused on the unique qualities of Canatu CNT, extensive customizability of the CNT synthesis and post-processing, and application potentials. See press release.

Developed for the European Space Agency’s future X-Ray space telescope the Athena, the optical filter using Canatu CNT could enable further visibility to space. See press release.

Canatu has the expertise to effectively adapt carbon nanotubes for different contexts and uses. The customizability and versatility of our synthesis process makes Canatu CNT ideal for highly engineered solutions. Discover differences.

The discovery of new things is deep in Canatu’s DNA. From the beginning, we have explored uncharted territory with curiosity. While our experts solve the issues of today, they are also working on what’s to come. To future developments.