Canatu CNT variants

Carbon is the most versatile material in the universe. We work with carbon on a molecular level to unleash its full potential. Our unique expertise is how we adapt the Canatu CNT to different contexts and uses. The extensive customizability of the Canatu CNT synthesis and post processing allows us to create the most advanced carbon nanotubes for highly engineered solutions. Our engineers and scientists are eager to discuss what kind of carbon nanotubes would add value in your specific applications.

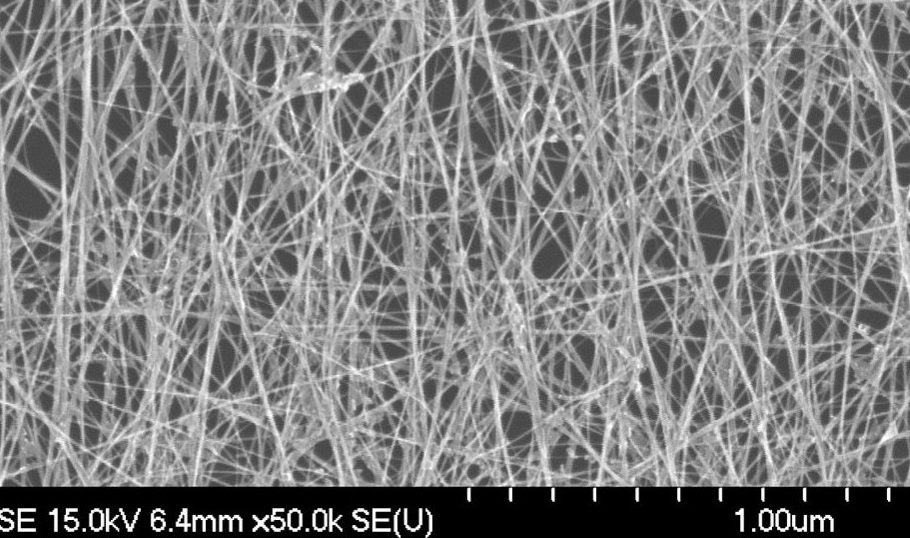

Single walled and multi walled CNTs

When synthesized using Canatu’s Floating Catalyst Chemical Vapor Deposition (FC-CVD), Canatu carbon nanotubes can be customized by the number of side walls to suit application specific requirements.

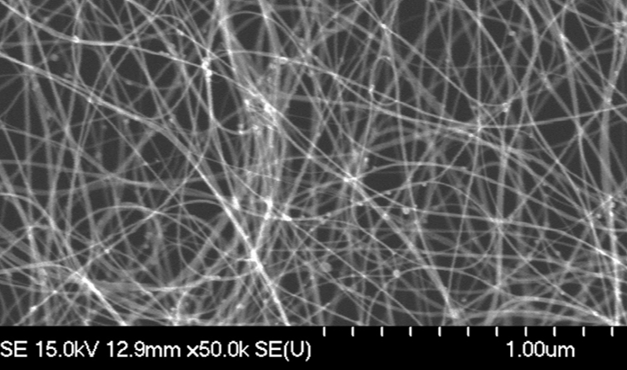

CNT orientation

Canatu has developed a special dry process for depositing carbon nanotubes onto any desired substrate or frame. The directionality or orientation of the CNTs can be controlled to create either isotropic or anisotropic CNT networks. This enables the customization of variable physical properties, such as optical, electrical, thermal, or mechanical in desired orientations and directions.

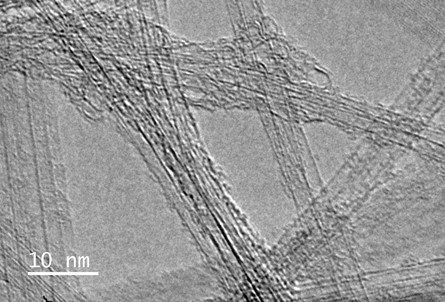

Bundle size control

Canatu´s unique synthesis and deposition process allows strict control over the CNT bundle size. Depending on the chosen conditions, CNTs can be induced to form larger or smaller bundles consisting of multiple parallel tubes. From application perspective, this network morphology customization can be used e.g. to enhance mechanical properties, to optimize coatings on CNTs, or to effectively decrease the total surface area of the CNTs exposed to chemically harmful environments. Bundle size tuning may also minimize scattering in EUV.

Catalyst removal

If desired, the metallic catalysts can be removed from the CNT network by different means without damaging the carbon nanotubes itself to further enhance optical and mechanical properties. The absence of catalyst particles can be especially useful in applications requiring high purity due to optical or chemical reasons.

Coating

In some cases, pure CNT structure is not enough. Canatu carbon nanotubes can be conformally coated with various organic and inorganic materials for added functionality. Coatings can be added onto the appropriate surface treatment. This way the optical, physical and chemical properties can be altered from those of pure carbon. Typical coating methods include atomic layer deposition (ALD), chemical vapor deposition (CVD) and physical vapor deposition (PVD).

Customizable CNT synthesis and post-processing

The fine structure and chemistry of the individual carbon nanotubes, as well as the mesoscopic morphology of the CNT network can be optimized extensively. In practice, this enables precise control over the number of walls in the carbon nanotube, the diameter of the carbon nanotube, and the size and type of catalyst particles. The orientation of the carbon nanotubes in the network can also be controlled, and the carbon nanotubes can be induced to form either larger or smaller bundles, resulting in dense or sparse networks with constant optical transmittance.

High degree of tunability is becoming increasingly critical in applications where strict particle and impurity filtering requirements must be met with minimal optical disturbances.

Canatu carbon nanotube surfaces can be further treated or coated in response to specific chemical or optical requirements. These characteristics are looking to truly answer the most demanding application environments. This fine tuning of the CNT synthesis conditions allows the fabrication of CNT networks with customizable optical properties, pressure drop, electrochemical reactivity, particle filtration properties and more.

The high tunability of the Canatu CNT opens the possibility for exploiting the material in a vast range of applications. CNTs are not “one size fits all”.

When combined with optimized morphology and additional surface treatments, the exceptional mechanical, optical, and thermal properties of Canatu CNTs make them attractive for a variety of applications.

Contact our specialist in core engineering

Send us a message

Related content

Canatu’s unique process is the secret to creating the most advanced carbon nanotubes for highly-engineered products. How we make Canatu CNT yields properties that make it applicable for a variety of industry-redefining products now and in the future. See our process.

Canatu CNTs are nucleated in a reactor and deposited onto a substrate at room temperature. Liquid dispersion step is eliminated. This unique dry process results in cleaner, longer and virtually defect-free carbon nanotubes benefiting applications where precision and reliability are vital. Discover differences.

Carbon nanotubes have unique mechanical, electrical, thermal, optical, and chemical properties. CNTs have very high tensile strength, high thermal and electrical conductivity, they are highly flexible and very elastic. Discover CNT properties.

Based on our expertise, we have developed manufacturing and product platforms that give us a scalable foundation for developing diverse solutions and applications. Find the fundamentals.

Canatu creates nano solutions for massive impact. We work with carbon, the most versatile material in the universe, and collaborate with other forerunner companies to make breakthrough innovations. See our company.