CNT is the material choice for EUV pellicles used in high power EUV scanners

Extreme ultraviolet (EUV) lithography is the driving force behind the mass production of advanced microchips with smaller node sizes. By enabling novel transistor design and chip manufacturing, EUV process continues to propel Moore’s Law forward, transforming products and entire industries. EUV pellicles are a key component in the lithography process, as they protect the mask (reticle) from particle contamination. Pellicles must be able to withstand extreme vacuuming and venting environments. Carbon nanotubes are emerging as the most promising material for EUV pellicles used in high-power EUV scanners, due to their mechanical and thermal properties.

The impact of EUV lithography technology is already evident in modern-day devices. Chances are if you own a relatively new smartphone, computer, or smartwatch you’re most likely experiencing the direct benefits of EUV technology. Within each of these devices are highly advanced microchips, which house billions of transistors. And with each new generation, chipmakers continue to increase the transistor density to create even more advanced chips. Using wavelength of 13.5 nm, EUV systems pattern the finest lines of the microchips. They are used in the high-volume manufacturing to create state-of-the-art microchips under 7nm.

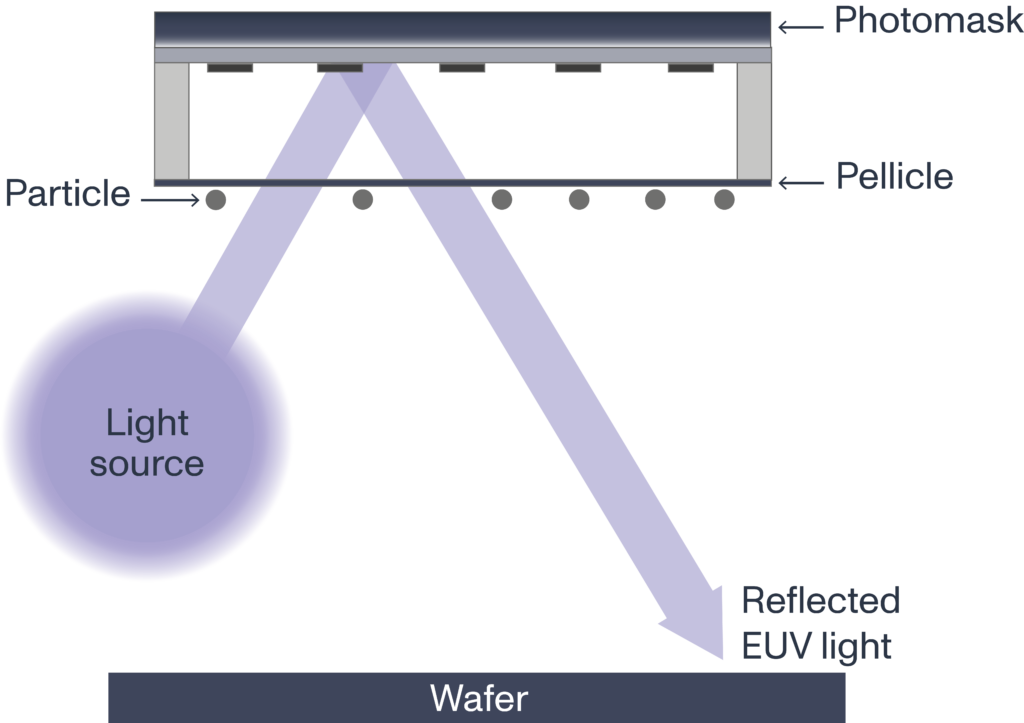

A key constraint affecting EUV lithography uptake is the risk of printing defects due to any build up of tiny particles. To mitigate this issue EUV pellicles are used, which protect the photomask (reticle) from particles. The EUV pellicles are placed inside the lithography machine just above the mask (akin to a stencil containing the blueprint of the pattern to be printed on the wafer), and their job is to filter nano-scale particles that would otherwise land on the mask, and be printed on the wafer, causing damage on the chips.

The next-generation high-NA ASML scanner will introduce high power levels exceeding 500 W, enabling the next step in efficiency. Nevertheless, higher power levels and mask (reticle) acceleration cause high heat loads and mechanical stress on the EUV pellicles. Due to their mechanical and thermal properties, carbon nanotubes are emerging as the most promising material for EUV pellicles.

Carbon nanotube pellicles can be made exceedingly thin with very high transparency at EUV wavelengths. This combined with the exceptional mechanical and thermal properties of carbon nanotubes can dependably provide a solution to the challenges of next-gen high-NA EUV lithography.

ASML recently mentioned at the SPIE conference held in San Diego in February 2023, that carbon nanotube is the most promising material for EUV pellicles for the high-power scanners.

Canatu has developed carbon nanotube pellicles with partners for already five years. The key benefits of the uncoated Canatu CNT membranes include high transmittance (>97%T at EUV), minimal flare (<0.2%), and high thermal stability in vacuum (>1500°C). High transmittance means more EUV light passes through the pellicle and reaches the wafer, increasing throughput. Low flare (scattering) ensures even the tiniest features can be printed on the wafer with high precision without pattern distortion. High heat resistance, chemical inertness and high tolerance to pressure differentials ensure our EUV pellicles can withstand vacuuming and venting cycles of the next-gen scanner environment while sustaining their optical properties.

Canatu and its partners have made significant progress in resolving the remaining challenges related to the pellicles’ lifespan in the hydrogen scanner environment. Since 2021, Canatu has been manufacturing CNT membranes for another EUV ecosystem device, demonstrating the scalability and repeatability of Canatu’s unique dry deposition process. Canatu’s unique carbon nanotube manufacturing method preserves the pristine quality of the carbon nanotubes, ultimately resulting in superior product performance.

Canatu’s vision is to create the most advanced carbon nanotubes for industry-transforming products, such as cutting-edge microchips, in support of the continuation of Moore’s Law.

Contact

Send a message

Related content

Semiconductors are all around us in every single electronic device we use. Progress in the semiconductor industry continues fast driven by Moore’s law. Canatu CNT plays a role in enabling industry breakthroughs. Read more.

EUV pellicles are used to protect the photomask from defects while permitting EUV light. Pellicles using the Canatu CNT offer unique properties, unequaled by any other material. See the product.

As EUV lithography becomes the norm for producing high-pitch patterning on wafers, the Canatu CNT will impact our everyday. “For me that’s the true sign on the Carbon Age”, said Ilkka Varjos, CTO of Canatu. Read the interview.

The world’s thinnest and strongest carbon nanotube membranes can be used as EUV pellicles to filter particles down to the nano scale, or as optical filters to cut certain wavelengths while permitting others. Discover more.