Carbon nanotube manufacturing

With Canatu’s unique process we are able to make many different kinds of carbon nanotubes. As we develop our process further, we will control manufacturing even more and create even more possibilities. Our unique process is the secret to creating the most advanced carbon nanotubes for highly-engineered products.

The way we manufacture Canatu CNT gives it its transformative potential for industry-redefining products now and in the future.

There are multiple ways that carbon nanotubes are manufactured. We have refined our process over the years, and it is fine-tuned to the point where we can ensure consistent quality.

Today, Canatu mass-produces its products for seven customers including reactors, sensors, and CNT membranes.

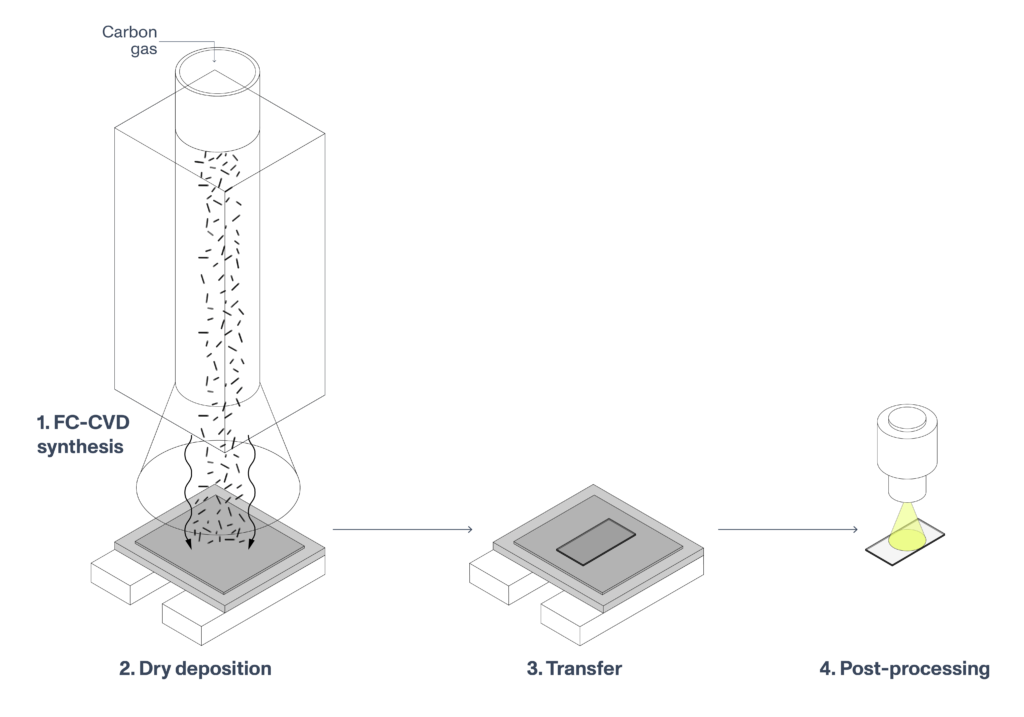

One unique characteristic of manufacturing Canatu CNT is that it is based on Dry Deposition™ rather than liquid dispersion. This results in cleaner, longer and practically defect-free carbon nanotubes. ln our process, described below, carbon nanotubes can be deposited on any substrate in atmospheric conditions.

Floating Catalyst Chemical Vapor Deposition

Canatu CNTs are synthesized using Floating Catalyst Chemical Vapor Deposition (FC-CVD) reactors. This yields high purity, strong CNTs of over 10um long, but only a few nanometers in diameter, enabling exceptionally thin, strong, and uniform CNT networks. However, controlling CNT growth in mass production is challenging. In fact, it has slowed down CNT becoming more widespread faster despite its remarkable properties. It is also why carbon nanotubes from a vendor may largely vary from batch to batch. Canatu has overcome these barriers.

Canatu’s unique process ensure consistent quality of the most advanced carbon nanotubes for highly engineered solutions.

When synthesized using FC-CVD reactors, catalyst particles are created at the top of the reactor. These particles float downwards with a carrier gas towards a membrane filter. As the catalyst particles flow through the reactor, carbon nanotubes grow on the catalyst particles. Canatu has developed a special method for depositing the CNTs directly onto any desired substrate or frame. This direct Dry Deposition™ process eliminates wet dispersion which can be detrimental to CNTs. The benefits of our carbon nanotube manufacturing method include being low-cost, readily scalable, and offering high control over the CNT growth, thereby ensuring optimal performance in the end applications.

In conductive films and electrochemical sensing applications, carbon nanotubes are transferred from the collection filter to a plastic substrate, before being chemically functionalized. Chemical functionalization serves to improve the conductivity and stability, whilst improving sensitivity and selectivity in electrochemical sensors.

In membrane applications, carbon nanotubes are transferred from the collection filter to a frame before going through post-treatments to modify or enhance properties. Possible post treatments include for example densification of EUV pellicles to ensure better adhesion of the CNTs to the frame material.

Dry Deposition™ vs. wet dispersion

Canatu CNTs are synthesized in a FC-CVD reactor and then dry deposited directly onto a desired substrate or frame at room temperature. This special direct Dry Deposition™ process eliminates any compromising steps, such as wet dispersion, resulting in cleaner, longer and virtually defect-free carbon nanotubes. This turns into better performance in end applications where precision and reliability are vital.

Canatu has exceptionally precise control over carbon nanotube manufacturing and the CNT structure. It is visible in how Canatu has industrialized CNT manufacturing. Further confirmation of the remarkability is that Canatu currently produces transparent conductive CNT film, which has the best industrially applicable sheet resistance to optical transparency ratio ever seen in CNT films with a sheet resistance of 35Ω/sq at 90% transmittance.

Record-breaking transparent conductive film

In 2021, Canatu made a world-record in commercial-scale manufactured carbon nanotube transparent conductive film transmittance and electrical conductivity. This significant achievement expands the potential applications for Canatu CNT and makes the material more affordable for automotive ADAS heater and flexible touch applications.

Mass production since 2015

Canatu has over a decade of experience in mass producing CNTs. Canatu conductive films and membranes are manufactured in a new factory in Finland. Built to support further manufacturing lines, the factory houses a fully automated roll-to-roll CNT film manufacturing line. Canatu has an additional manual film production line and sensor prototyping at its factory. This enables fast turnaround samples and small-scale production to support customers from initial concept to mass development and all the way through to mass production.

The best illustration of Canatu’s manufacturing experience and expertise is the lack of field returns. Back in 2015, Canatu had initially delivered half a million touch sensors without any field returns under the company’s first mass production order for a transparent touch controller.

“Thanks to our well-controlled process, the field return rate remains at zero, and we keep getting positive customer feedback month after month. This is concrete proof that our technology solves real customer needs and meets the stringent requirements of the automotive industry”

Markku Lamberg, VP of Customer Projects and Supply Chain

This level of consistency and reliability continued strong over the years. By 2022, Canatu had delivered nearly 1M touch sensors with a field return rate of zero.

Contact

Send us a message

Related content

Canatu’s patented Dry Deposition™ method unlocks the full potential of carbon nanotubes (CNTs) with massive implications for the semiconductor industry. This method simplifies the process reducing steps and cycle time, producing longer, pristine CNTs with superior EUV transmission, tensile strength, and more uniform CNT networks compared to the traditional wet dispersion process. Read the article.

Through experience, we have achieved consistent quality and properties with carbon nanotubes, which gives Canatu CNT transformative potential. Delve deep into carbon nanotubes.

Carbon nanotubes have unique mechanical, electrical, thermal, optical, and chemical properties. CNTs have very high tensile strength, high thermal and electrical conductivity, they are highly flexible and very elastic. Discover CNT properties.

Based on our expertise, we have developed manufacturing and product platforms that give us a scalable foundation for developing diverse solutions and applications. Find the fundamentals.

Based on our expertise, we have developed manufacturing and product platforms that give us a scalable foundation for developing diverse solutions and applications. Find the fundamentals.