Dry deposition vs. wet dispersion

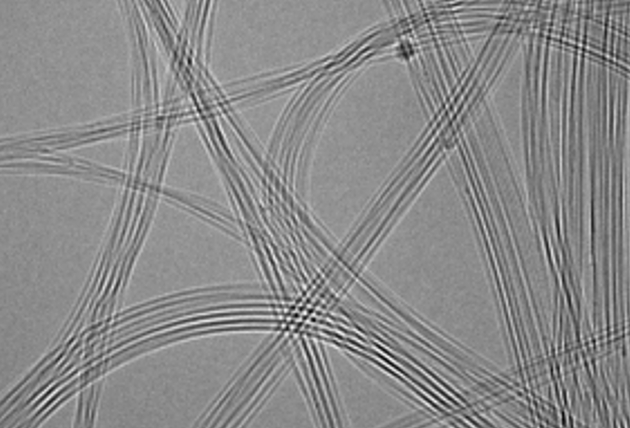

Canatu’s dry deposition method creates incredibly long and pristine CNTs and is in many ways superior to traditional wet dispersion of CNTs. Traditional liquid dispersion of CNTs requires several complex process steps. With dry deposition, the process is simpler, faster, and more cost effective than ever before. Dry deposition bypasses many complex steps present in wet dispersion, which may cut and damage CNTs, resulting in high-purity, strong CNTs.

Canatu’s dry deposition method outperforms traditional liquid dispersion, by simplifying the process, producing longer and cleaner CNTs, and creating highly uniform CNT films.

Our process gives you the advantage, enabling your product to perform just the way you intend them to. Our method yields longer, cleaner, and nearly defect-free CNTs with superior uniformity, transmittance, electrical conductivity, and tensile strength, enhancing performance across applications.

Semiconductor fabricators can benefit from Canatu’s dry deposition method to create CNTs with excellent uniformity and high transmittance benefitting a range of applications, such as EUV pellicles, debris filters, and more.

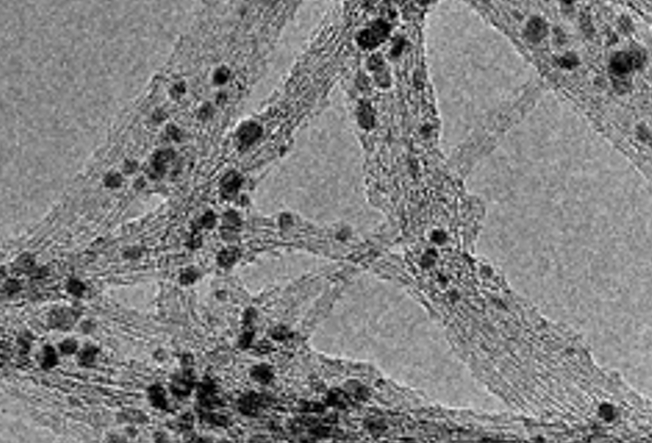

In contrast, ultrasonication and surfactants in traditional liquid dispersion can damage CNTs, leading to shorter and less pristine tubes, reduced tensile strength by up to 85%, bundling, and decreased electrochemical sensitivity.

Wet dispersion

The traditional liquid dispersion method starts with CNT powders and requires multiple complex and expensive processing steps. The method involves ultrasonication, which is detrimental to CNTs, resulting in shorter and less pristine carbon nanotubes, thus reducing tensile strength by up to 85%. This deterioration affects mechanical, thermal, and chemical properties, while also causing CNTs to bundle together. Additionally, defects in the CNTs lower their electrochemical sensitivity.

Dry deposition

Canatu completely bypasses the ultrasonication and liquid dispersion steps. In our cutting-edge dry deposition method, carbon nanotubes are deposited on a collection filter at room temperature.

This yields longer, cleaner, and virtually defect-free CNTs. In principle, electrical conductivity and tensile strength of the tubes increase with their length and purity, enhancing properties and performance across various applications.

Floating catalyst chemical vapor deposition

Canatu synthesizes CNTs using the floating catalyst chemical vapor deposition (FC-CVD) process. Compared to other methods, FC-CVD stands out as a low-cost, highly controllable, and scalable process for creating cutting-edge CNTs for industry-transforming products.

During FC-CVD, CNT growth is initiated by introducing carbon gases into the reactor. The furnace is then heated to vaporize and decompose the carbon gases, leading to catalyst particles forming at the top of the reactor. These particles float down the reactor with a carrier gas toward the collection filter. As they drift down the reactor, carbon nanotubes (CNTs) start to grow on the catalyst particles. The CNTs are direct dry deposited onto the collection filter and subsequently transferred onto either a plastic substrate, creating a conductive film, or a frame, creating a membrane.

Dry deposition of carbon nanotubes

Canatu’s process not only start out with higher quality CNTs, but also maintains the quality of these materials on the substrate. This does away with material degrading, hazards, acid treatments, sonification, surfactants or functionalization, which only serve to undermine the quality of the CNTs.

Dry deposition method allows performance components to be easily produced in a more rapid, economical and environmentally sound procedure

Compared to other techniques such as nanomaterial printing using inks, dry deposition method reduces the number of steps to make deposits and increases the performance of the final products. In some cases, waste products from other industrial processes can even be recycled to produce Canatu’s carbon nanomaterials, making this process more environmentally friendly.

Liquid dispersion cuts and damages CNTs

Traditional CVD synthesis and the liquid dispersion of CNTs is a complex process with several steps. It starts with CNT powder, which often comes with bundles, impurities, and low crystallinity. Ultrasonication cuts the longer CNTs into pieces. As a result the aspect ratio of CNTs decreases, degrading their properties.

- CVD synthesis

The catalyst-coated ceramic plate is placed inside the reactor, and carbon-containing gas is introduced. Carbon atoms from the feedstock react with the catalyst, leading to the growth of carbon nanotubes. The CNTs grow vertically from the catalyst particles, forming a forest-like structure. - CNT powder collection

After synthesis, CNTs are collected from the ceramic plate. CNT powder usually comes bundled with impurities and has low crystallinity. - Liquid dispersion and ultrasonication

The collected CNT powder is dispersed into the liquid and blended with water using ultrasonication. While this step effectively mixes CNTs with the water, it also results in cutting the CNTs. As a result, the aspect ratio of CNTs decrease, degrading their properties. - Purification

Next, CNT undergoes purification to remove metallic catalyst residues using an acid-based method. Residual metals are particularly undesirable in the EUV applications as they can absorb and scatter the EUV light. - Introducing surfactants

Surfactants are added to improve the dispersity of CNTs. CNT bundles improve mechanical strength but degrade optical performance causing scattering. - Separation

CNTs are separated based on their structural and purity properties. - Filtration

The membrane is introduced into the water, and the floating CNT network is subsequently filtered onto it. - Water transfer printing

The CNT network is detached from the filter on the liquid’s surface. Then, a frame is pulled through the liquid, attaching the CNT network onto it, creating a freestanding CNT network. - Purification

Residual surfactants are washed away. - Coating

Coatings can be applied to the CNT membrane to improve its stability in the EUV environment.

Contact our specialist in dry deposition process

Send us a message

Related content

Canatu’s unique process is the secret to creating the most advanced carbon nanotubes for highly-engineered products. How we make Canatu CNT yields properties that make it applicable for a variety of industry-redefining products now and in the future. See our process.

Based on our expertise, we have developed manufacturing and product platforms that give us a scalable foundation for developing diverse solutions and applications. Find the fundamentals.

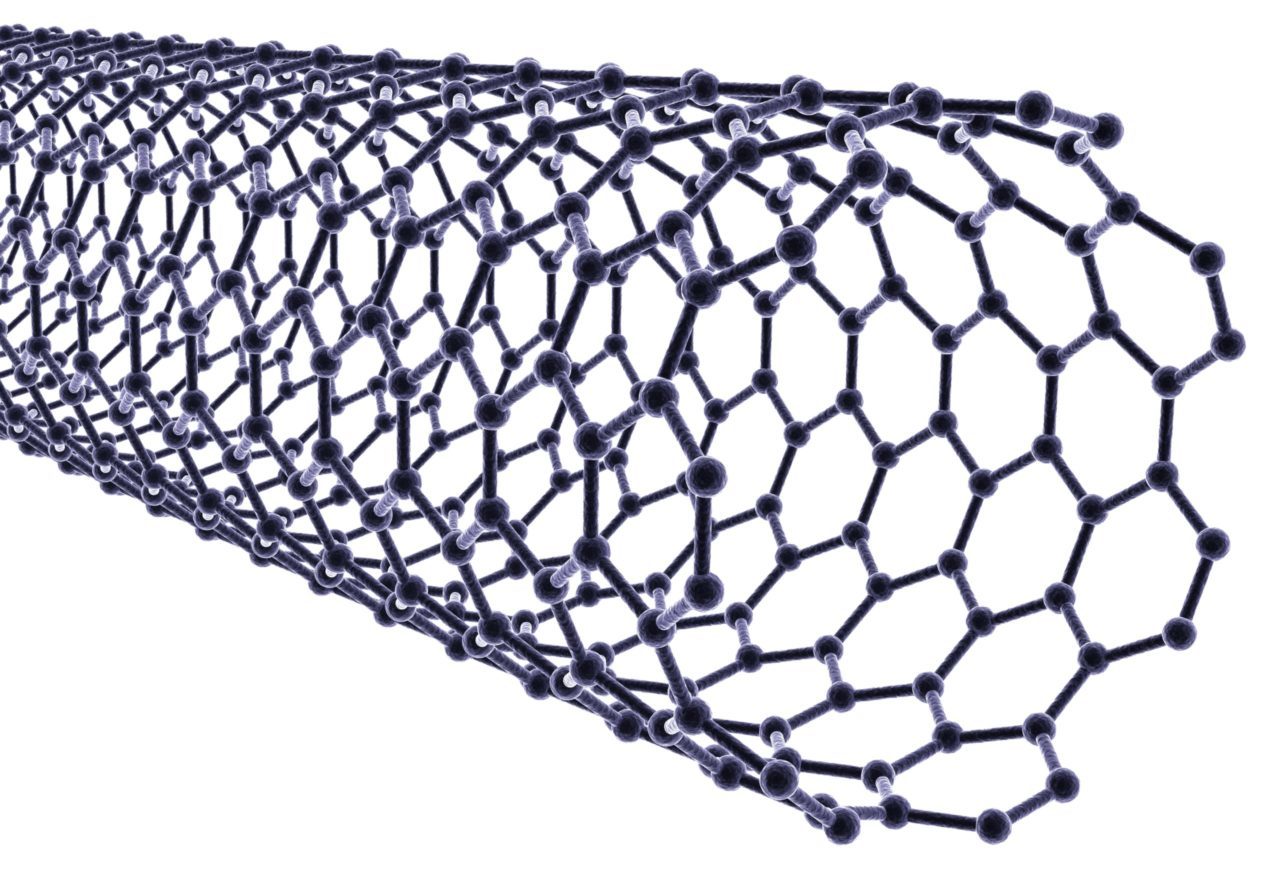

Carbon nanotubes have unique mechanical, electrical, thermal, optical, and chemical properties. CNTs have very high tensile strength, high thermal and electrical conductivity, they are highly flexible and very elastic. Discover CNT properties

Through Canatu’s unique manufacturing process, we can control the number of walls each carbon nanotube has. This allows Canatu to produce single, double, and multiple walled carbon nanotubes suitable for a variety of applications. Discover differences.