Products

We develop, create and deliver unique technology and products. Canatu CNT is used in highly engineered solutions, where precision, performance and reliability are vital.

Transforming products for better tomorrows

We develop, create, and deliver unique technology and products. Through our process, we create carbon nanotubes with qualities that set them apart from the others. Our unique expertise is how we adapt CNT to different contexts and uses. In partnership with forerunners, we innovate breakthroughs with the potential to redefine industries. The Canatu CNT is used in highly engineered solutions, where precision, performance and reliability are vital.

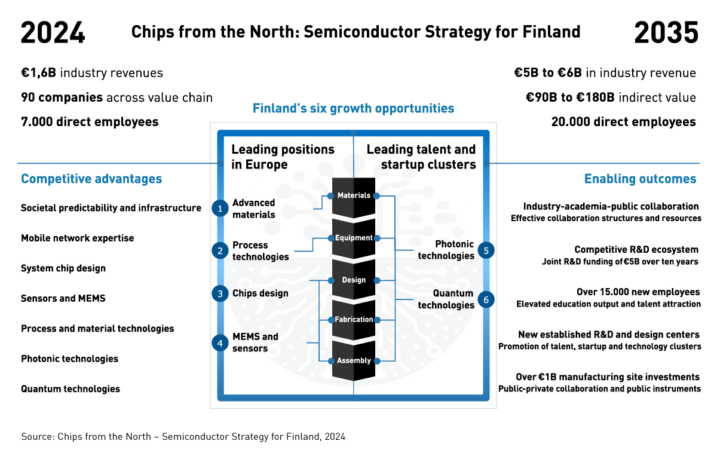

Our main focus today is on the semiconductor and automotive industries. We continuously expand what is possible with nano carbon, searching for new opportunities.

Products by industry

We enhance precision and throughput of high-NA semiconductor manufacturing with the world’s thinnest and strongest free-standing EUV membranes.

We enable autonomous driving in any weather with Canatu CNT film heaters for LiDAR and camera sensor de-icing.

We advance medical diagnostics by bringing lab-level tests everywhere, making sure saving lives is no longer about cost of care or lack of information.

Our tiny solutions have the potential to create a massive impact. Carbon nanotubes are on track to overtake silicon as transistors, and they can be used as optical filters for EUV and X-Ray filters found in telescopes and imaging.

Setting new benchmarks in industrialization

Canatu collaborates with DENSO to develop high-performance reactors for CNT film manufacturing. This collaboration is aimed at effectively tripling Canatu’s current CNT film manufacturing productivity. The Joint Development Agreement signifies a key milestone in Canatu and DENSO’s long-standing business partnership.

Together with our partners

We collaborate with companies who are looking to transform industries. Through collaborations in our ecosystems, we expand our expertise to industry-transforming solutions.

Through collaborations, what we create becomes part of solutions with the power to transform products, industries, and even everyday life.

With the automotive industry, we are transforming the driving experience. We advance autonomous driving in any weather with the Canatu CNT film heaters for ADAS cameras and LiDARs. We also shape surfaces into experiences possible with touch sensors in any form factor.

With the semiconductor industry, we are advancing the EUV lithography uptake with the world’s thinnest and strongest free-standing membranes. These sophisticated filters can be used as EUV pellicles to protect the photomask (reticle) from contamination.

With healthcare, we are advancing electrochemical sensors for measuring opioid concentrations in blood. With this, anyone can have an easy access to affordable diagnostics at the point-of-care.

Canatu CNT is a highly versatile material, suitable for many uses. We continuously search for new possibilities to transform products for better tomorrows with nano carbon.

Contact

Send us a message

Related content

Carbon nanotubes have unique mechanical, electrical, thermal, optical, and chemical properties. CNTs have very high tensile strength, high thermal and electrical conductivity, they are highly flexible and very elastic. Discover CNT properties.

Canatu product and manufacturing platform gives a solid core that enables diverse solutions and applications. Read more.

Canatu’s unique process is the secret to creating the most advanced carbon nanotubes for highly-engineered products. How we make Canatu CNT yields properties that make it applicable for a variety of industry-redefining products now and in the future. See our process.

Canatu CNTs are nucleated in a reactor and deposited onto a substrate at room temperature. Liquid dispersion step is eliminated. This unique dry process results in cleaner, longer and virtually defect-free carbon nanotubes, benefiting applications where precision and reliability are vital. Discover differences.

Canatu has the expertise to effectively adapt carbon nanotubes for different contexts and uses. The customizability and versatility of our synthesis process allows us to create the most advanced CNTs for highly engineered solutions. Read about versatility.