Carbon nanotube uses

The learning curve with carbon nanotubes has been fast. Its development has been supported by parallel progress in nanotechnology and other technological advances.

The manufacturing of carbon nanotubes yielded haphazard quality when it started to be developed after being properly discovered around three decades ago. Different kinds of CNT were produced randomly. Therefore, its only uses were for rudimentary applications. Through research in laboratories more and more was learned about achieving specific kinds of nanotubes consistently.

Where in the past carbon nanotubes only led to incremental impact, today the developed manufacturing process and consistent quality means their impact is transformative.

CNT has become a relevant option for highly engineered solutions. In the automotive industry, early uses were on the gas pump holder to avoid electric static. Carbon nanotubes were used to replace carbon black, saving material and financial resources. Nowadays, the role of carbon nanotubes for the automotive industry is more transformative: Canatu CNT supports developing the autonomous driving experience.

Primed for highly developed solutions

The more rudimentary uses are still around with carbon nanotubes still used in e.g. batteries. These uses are more akin to adding “salt to the salad” rather than CNT being one of the main ingredients.

Because of this, our focus is purely on highly engineered solutions where the role of carbon nanotubes is transformative. It is a result of honing our own process – which is entirely in our own hands – and having highly developed expertise in manufacturing through experience.

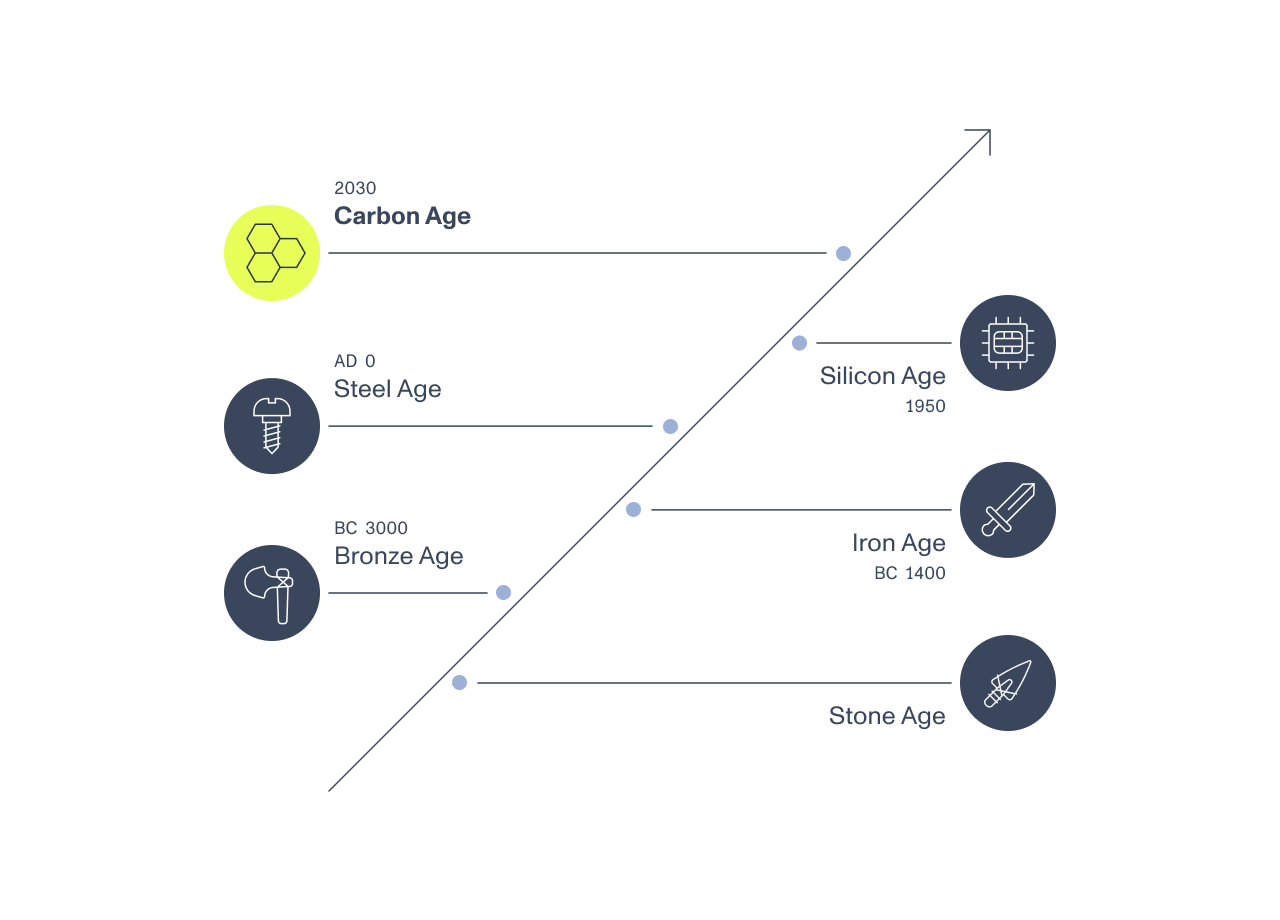

From the silicon age to the carbon age

Carbon is a future-proof material. Working with nanotechnology taps into its outstanding versatility and allows us to replace materials with a negative environmental impact. Canatu is accelerating the arrival of the new age by innovating with nano carbon.

Aligned with technological progress

Our application of carbon nanotubes is not dependent of market trends. They come and go as do different issues industries struggle with. It is more about looking at where technology is moving and what role CNT can play in future processes and products.

At the same time, technological progress makes the market more open to nanotechnology and applying carbon nanotubes to innovative products. Understanding of the possibilities of nanotechnology and the existence of CNT is growing all the time.

More and more solutions are being made in the smaller scale for the simple reason that we are able to see tinier scales. This expands what is possible For instance, 20 years ago transistors were a few dozen nanometres in size, whereas now we are looking at single-digit nm in size.

Mass production of carbon nanotubes

Canatu has been involved in mass production of carbon nanotubes for the automotive industry since 2015 and the semiconductor industry since 2021. It has taught us to tame the process. With more control we are able to deliver different kinds of carbon nanotubes for specific uses more consistently. Knowledge of the process increases repeatability and adaptability of Canatu CNT.

Carbon nanotubes go way back

The discovery of carbon nanotubes is widely attributed to Sumio Iijima in 1991. Attributing the discovery to him doesn’t mean that it is the first appearance of carbon nanotubes. In fact, when scientists studied ingenious rocks from 250 million years ago, they had found micro and nano carbon tubes.

This material of high tech innovation is actually quite ancient by nature. Today, we are able to see what we are doing, controlling the manufacturing and application, unlike the blacksmiths hundreds of years ago.

Early this century, Marianne Reibold and colleagues from the University of Dresden discovered that the secret of 17th century Damascus swords was also CNT, according to National Geographic magazine (Sept 2008). The blades were made from wootz steel that has exceptionally high carbon content – so high they should’ve been too brittle to make worthwhile swords. Closer inspection revealed that the steel is a composite material at a nanometre level, making it so strong – and the carbon nanotubes played a major role in the blade’s durability. How the nanotubes were produced by the blacksmiths is unclear but suspect the many metals in the wootz and alternating hot and cold phases in manufacturing played a role.

Contact our specialist in Carbon nanotube uses

Send us a message

Related content

Through experience, we have achieved consistent quality and properties with carbon nanotubes, which gives Canatu CNT transformative potential. Delve deep into CNT.

The discovery of new things is deep in Canatu’s DNA. From the beginning, we have explored uncharted territory with curiosity. While our experts solve the issues of today, they are also working on what’s to come. See future developments.

Our main focus today is in the automotive and semiconductor industries. We continuously expand what is possible with nano carbon, searching for new opportunities. Work with Canatu CNT.

Our solid foundation gives us a clear direction. When we collaborate with forerunners, together we create the potential to transform industries and impact everyday life. To our vision.