CNT membranes

Advanced CNT membranes, customized for application-specific needs. Increase productivity in high-power EUV lithography as CNT pellicle membranes, enhance quality control in patterned mask inspection, and enable selective wavelength filtration in optical filters. Made from the most advanced carbon nanotubes, renowned for their exceptional purity and properties.

Canatu CNT membranes: a versatile platform technology

The semiconductor industry is rapidly evolving, driven by AI and computing advancements, with sub-7nm chips made using EUV technology growing the fastest. Canatu is a key technology supplier for EUV, providing advanced carbon nanotube (CNT) products and reactors for the semiconductor industry.

Canatu’s advanced CNT membranes support various EUV applications, including CNT pellicle membranes for high-power EUV lithography, protecting photomasks from defects and increasing productivity, inspection membranes for patterned mask inspection and mask blank inspection, filtering debris and improving quality control, and optical filters for selective wavelength filtration. In addition to CNT products, we offer CNT reactors and technology licensing, enabling in-house production of advanced CNT products.

- High EUV transmission >97%

- High thermal stability >1500°C in vacuum

- Exceptional mechanical strength

- Customized for application-specific requirements

Download technical paper

Please download the most recent 2023 SPIE Photomask + EUVL Conference proceedings to gain deeper understanding of our versatile platform technology, unique CNT synthesis and direct dry deposition benefits, common tailoring, and potential uses for our carbon nanotube membranes.

Download technical paper

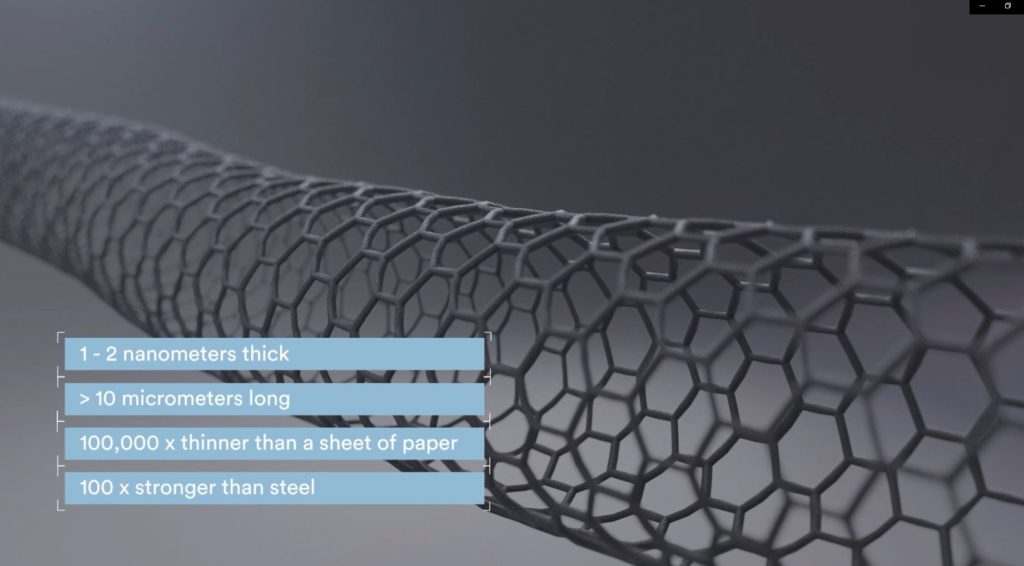

Canatu CNT properties

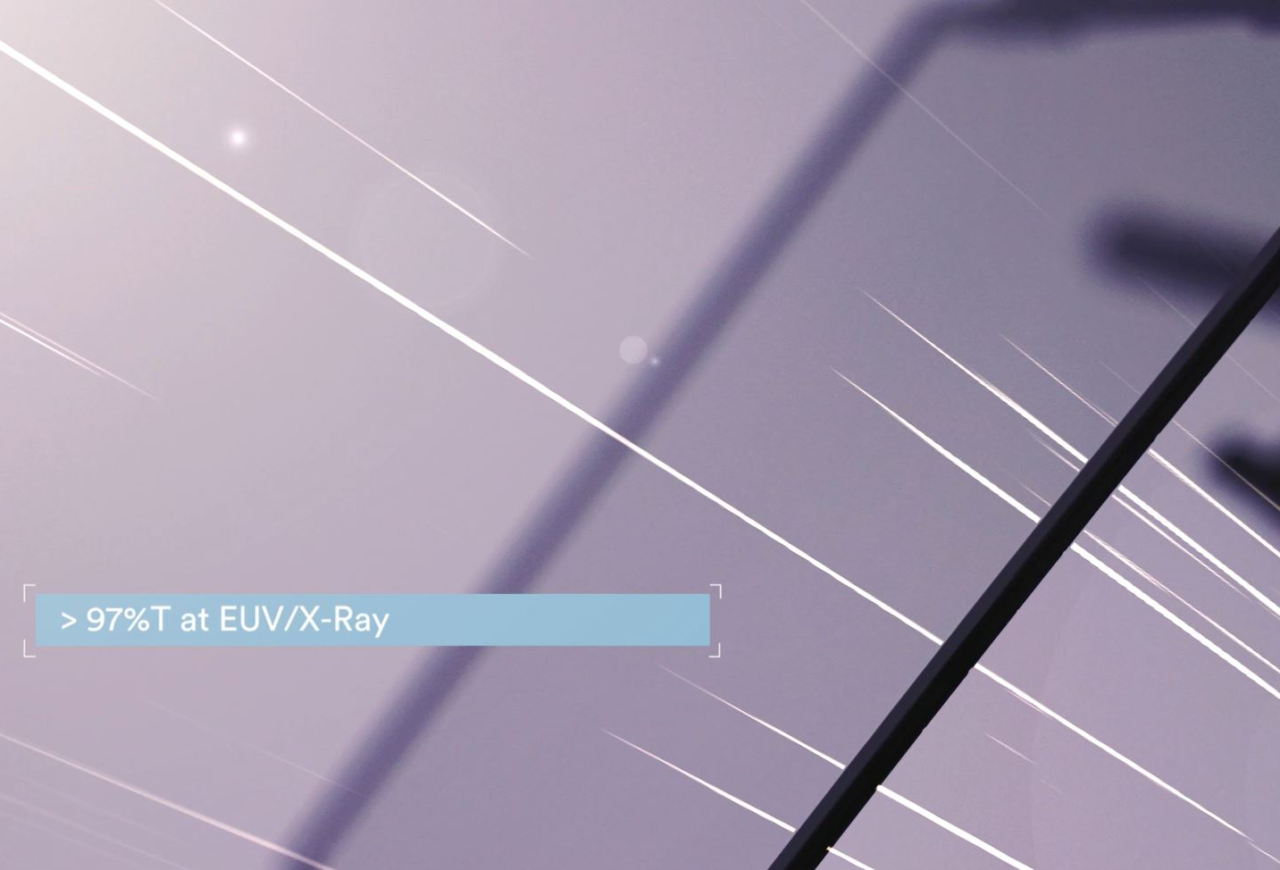

High transmittance

Canatu’s ultra-thin CNT membranes provide up to 97% transmission at EUV/X-ray wavelengths with minimal scattering, ensuring precise pattern printing. In EUV pellicle applications, higher transmission allows more EUV light to reach the wafer, enhancing throughput. Canatu CNT pellicle membranes support productivity increase potential in EUVL by up to 8–15%.

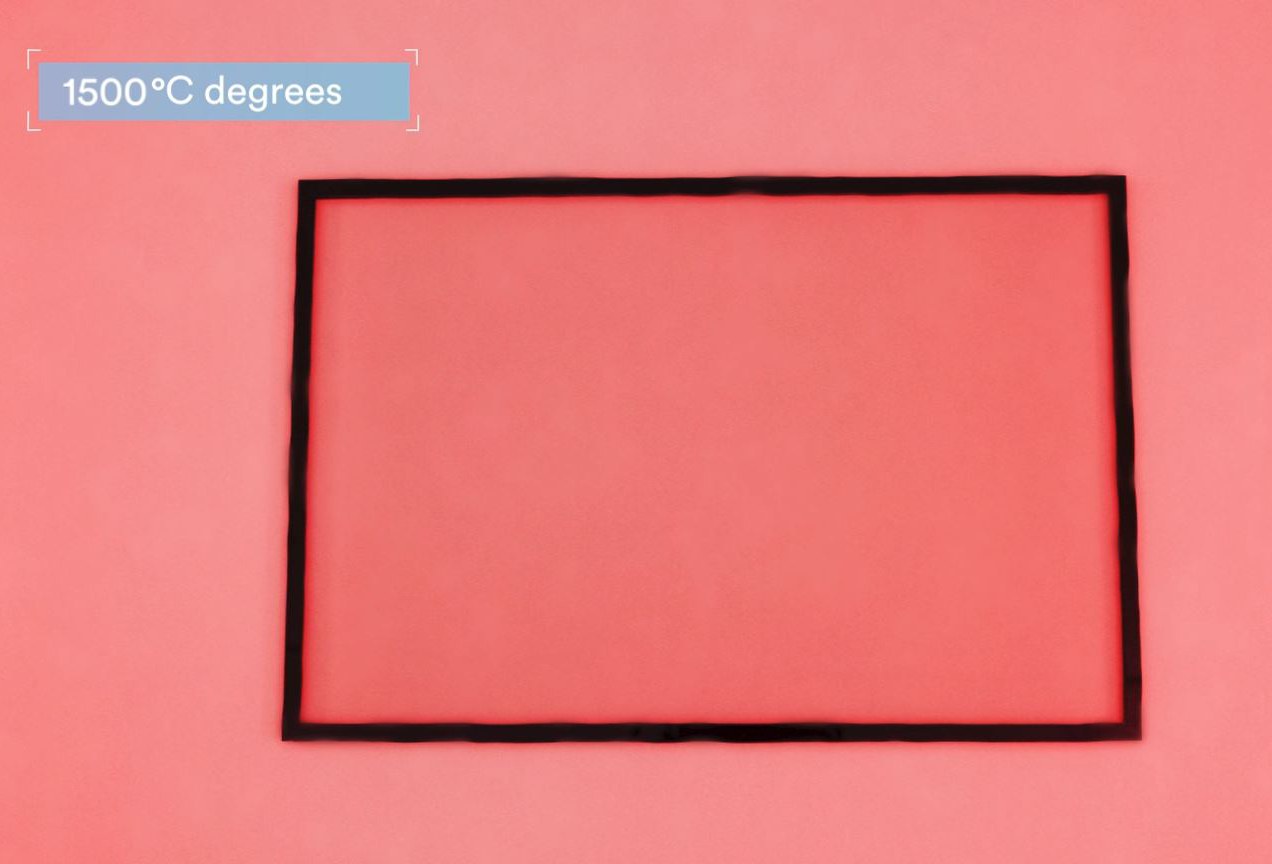

High heat resistance

Canatu CNT membranes offer exceptional heat resistance, enduring extreme temperatures without degradation or structural damage. They can withstand up to 1500°C in a vacuum, outperforming quartz, which breaks at 1200°C, and polyimide, which decomposes below 520°C.

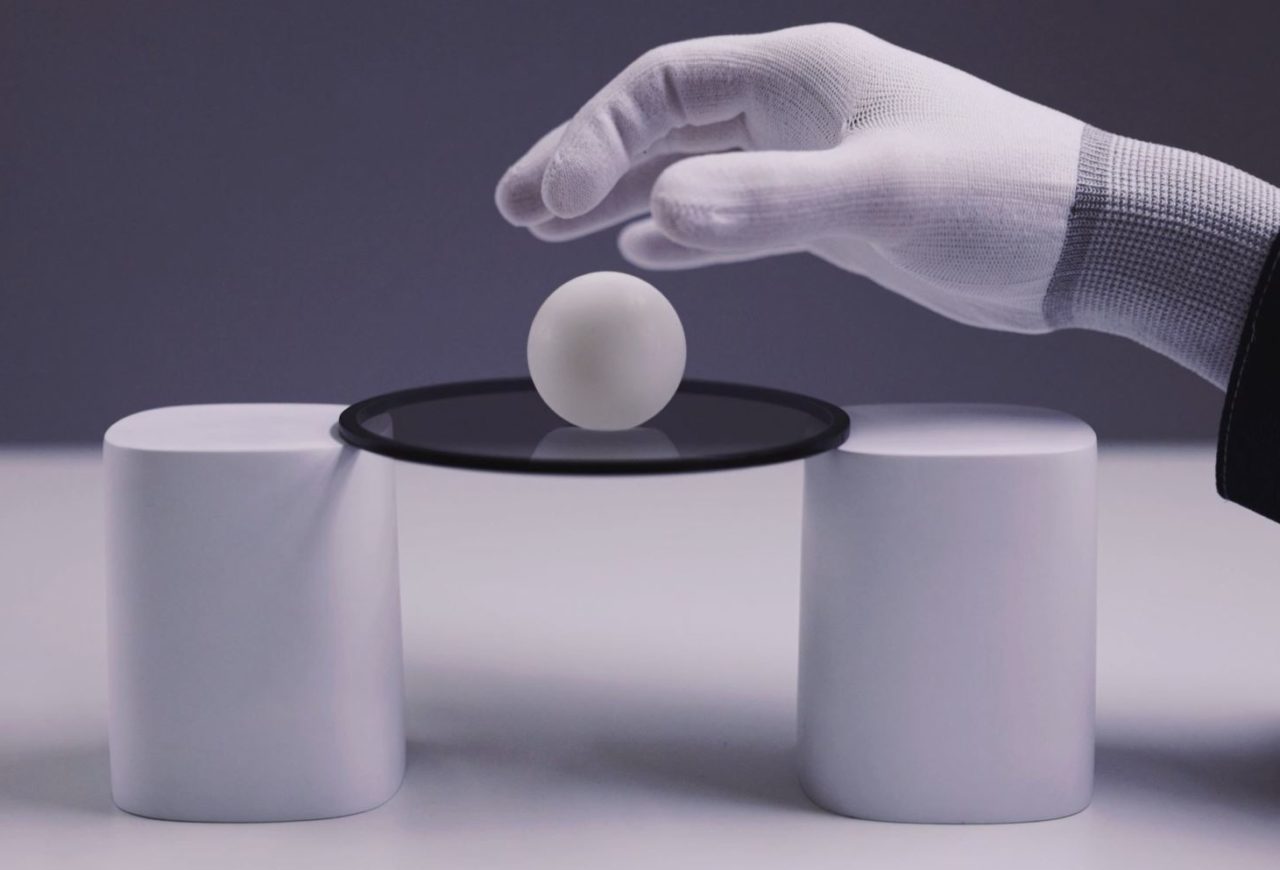

High mechanical strength

The high tensile strength of one-dimensional carbon nanotubes makes the two-dimensional membranes mechanically robust. Their slight elasticity allows them to withstand unexpected mechanical loads without breaking or shattering. In CNT pellicle and inspection membrane applications, this elasticity helps protect system integrity in case of accidents or unforeseen events.

Differentiated, IPR protected technology

Patented Dry Deposition process

- Canatu Dry Deposition process brings significant material advantages over wet dispersion

- Simpler, faster process yielding high-purity, strong CNTs enabling better performance in end applications

- Platform technology that is easy to expand into new applications or products

Advanced CNTs are primed for high-value applications

- Extremely versatile, offering extensive customization enabling tailored solutions

- 137 patents and 76 patent applications across 39 distinct families, along with trade secrets (e/2024)

- A “quality game” produced in hundreds of grams vs. “bulk” CNTs that are produced in tonnes

- Difficult to manufacture at industrial scale

Proven and efficient mass production capability

- Mass production of CNT products since 2015. Over 1,1M CNT sensors delivered with FRR 0.

- Mass-producing inspection membranes for debris filtration in patterned mask inspection since 2021

- Successful customer shipments of the first two S-100 reactors for CNT pellicle membrane production in 2024

Broad potential applications

- High-power EUV lithography

- Patterned mask inspection

- Mask blank inspection

- Optical filtration

Our products

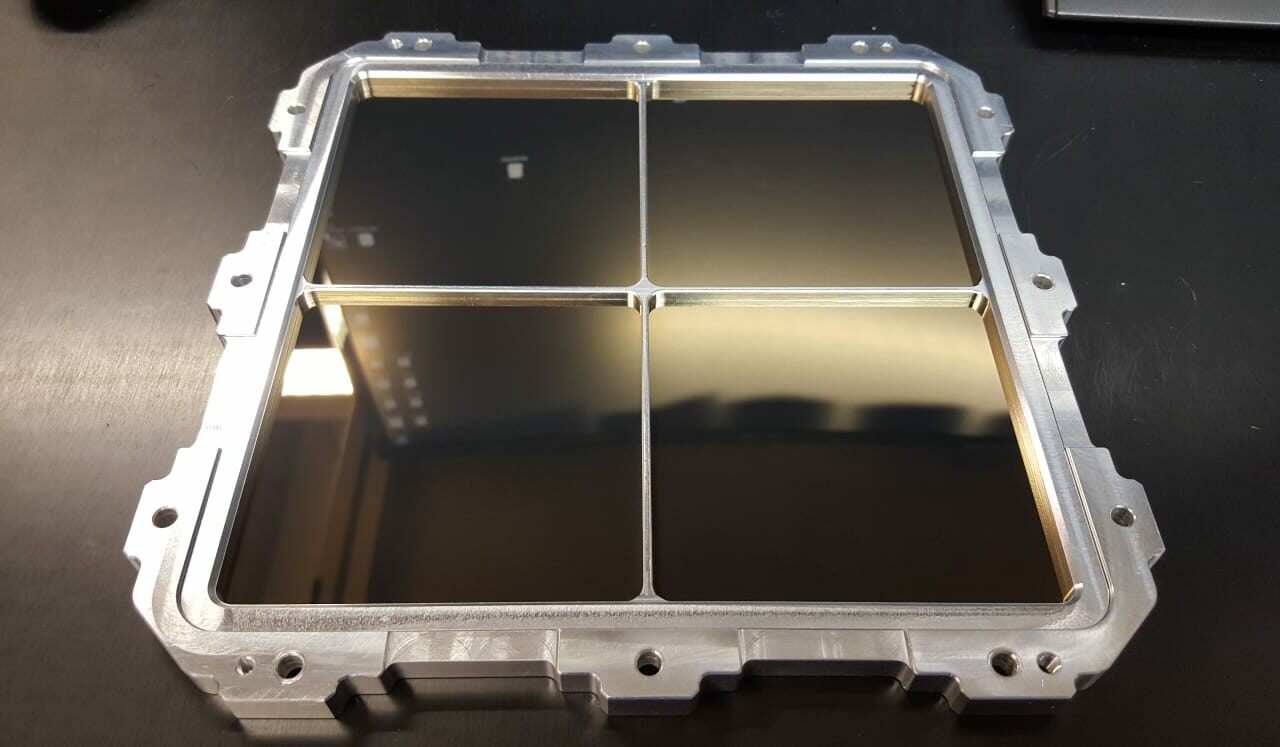

Canatu CNT pellicle membranes protect photomasks from particle contamination in high-power (>500W) EUV lithography machines. With high EUV transmittance, exceptional strength, and thermal stability up to 1500°C in a vacuum, they outperform conventional composite pellicles in handling extreme heat and mechanical stress of next-gen EUVL machines. Canatu CNT pellicle membranes can increase EUVL productivity by up to 8-15%.

Canatu inspection membranes are suitable for patterned mask inspection, EUV mask blank inspection, and optical filtration, enhancing quality control in pre- and post-lithography processes. They filter debris from the EUV light source, preventing contamination of sensitive and costly optics or masks to ensure defect-free processes.

Coated CNT membranes provide selective wavelength filtering, blocking unwanted particles, electrons, and photons (e.g., DUV, VIS, IR) while ensuring high EUV and X-ray transmittance.