Reactors

Tailor-made CNT reactors for industrial scale production of carbon nanotubes

Canatu designs and manufactures custom CNT synthesis reactors and licenses its technology, enabling customers to produce CNT products under a limited license. Our CNT100 SEMI reactor is tailored for high-precision CNT membrane production in the semiconductor industry, while the CNT100 HPR reactor is optimized for high-volume conductive film production in automotive and medical diagnostics applications. Canatu also provides consumables, lifecycle services, and spare parts to ensure uninterrupted reactor operation. Our proprietary floating catalyst chemical vapor deposition (FC-CVD) reactors and Dry Deposition™ process deliver advanced carbon nanotubes for highly engineered solutions.

Reactor products

We sell CNT reactors and license our technology, allowing customers to produce CNT products themselves. We offer customized solutions specifically tailored to your needs. Our lineup includes:

- CNT100 SEMI reactors (formerly S-100 reactors): Custom-designed for producing high-precision CNT membrane products.

- CNT100 HPR reactors (formerly H-100 High-Performance reactors): Engineered for high-volume CNT film production and seamless integration into fully automated roll-to-roll film production lines.

Additionally, we provide peripherals and consumables to upgrade your equipment and ensure continuous, high-performance operation.

CNT100 SEMI features

- Precision optimized

- One tube

- Tailor-made collection chambers (1-2), A3 size

- Stand-alone

- Typical applications: CNT membranes

CNT100 HPR features

- High performance

- Film production

- Two tubes

- Large size 600x600mm collection chambers (1-n), standard and orientated

- Multiple reactors integrated into one automation line

- Typical applications: film heaters and sensors

Applications

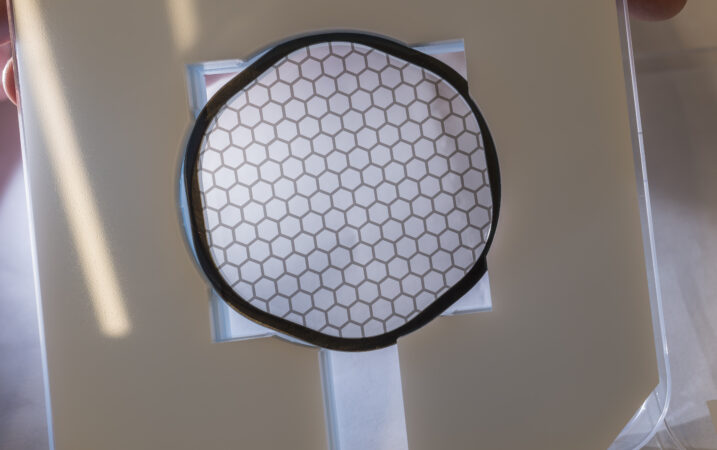

- CNT pellicle membranes for blocking defects

- Inspection membranes for debris filtering in patterned mask inspection

- Optical filters for blocking DUV/VIS while passing EUV/X-Ray

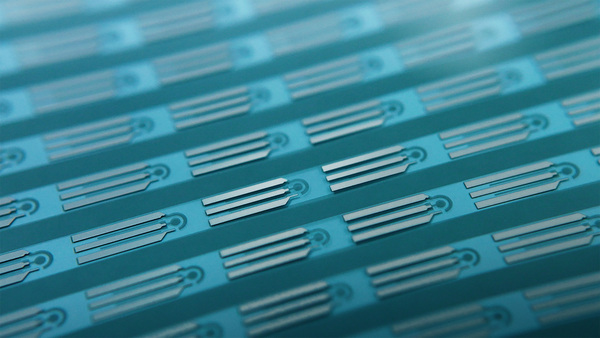

- Film heaters for automotive ADAS sensor de-icing and defogging

- Electrochemical biosensors for medical diagnostics

Functionalization and post-processing

Canatu has extensive experience in controlling CNT growth and variation during Floating Catalyst Chemical Vapor Deposition (FC-CVD) synthesis and in designing CNT reactors, ensuring cost-efficient carbon nanotube manufacturing on an industrial scale.

Both reactor types are suitable for SWCNT and MWCNT products. FC-CVD synthesis allows tuning of CNT diameter, wall count, (SWCNT or MWCNT), network density, orientation, and bundle size, making it a versatile material platform. With tailored orientation chambers, we can control the orientation of CNTs. CNTs can be further modified through post-processing, such as purification to remove residual metals from the synthesis or functionalization to match the specific deposition chemistry required by coating processes.

CNT reactors for highly engineered solutions

By combining FC-CVD synthesis reactors with a Dry Deposition method, our customers can create CNT membranes with exceptional uniformity, high EUV transmittance, strength, and purity. Thicker CNT membranes are suitable for various applications such as filtering debris from the EUV source, blocking deep-ultraviolet (DUV) photons, or providing a gas seal for differential pressure.

Canatu CNT membranes are also ideal for X-Ray filter applications due to their high X-Ray transmittance, resistance to pressure differentials, and chemical inertness. These optical filters can be placed in front of an X-Ray detector to block particles, electrons, and photons outside the desired energy range while maintaining high X-Ray transmittance and withstanding high temperatures and differential pressure conditions.

Latest news

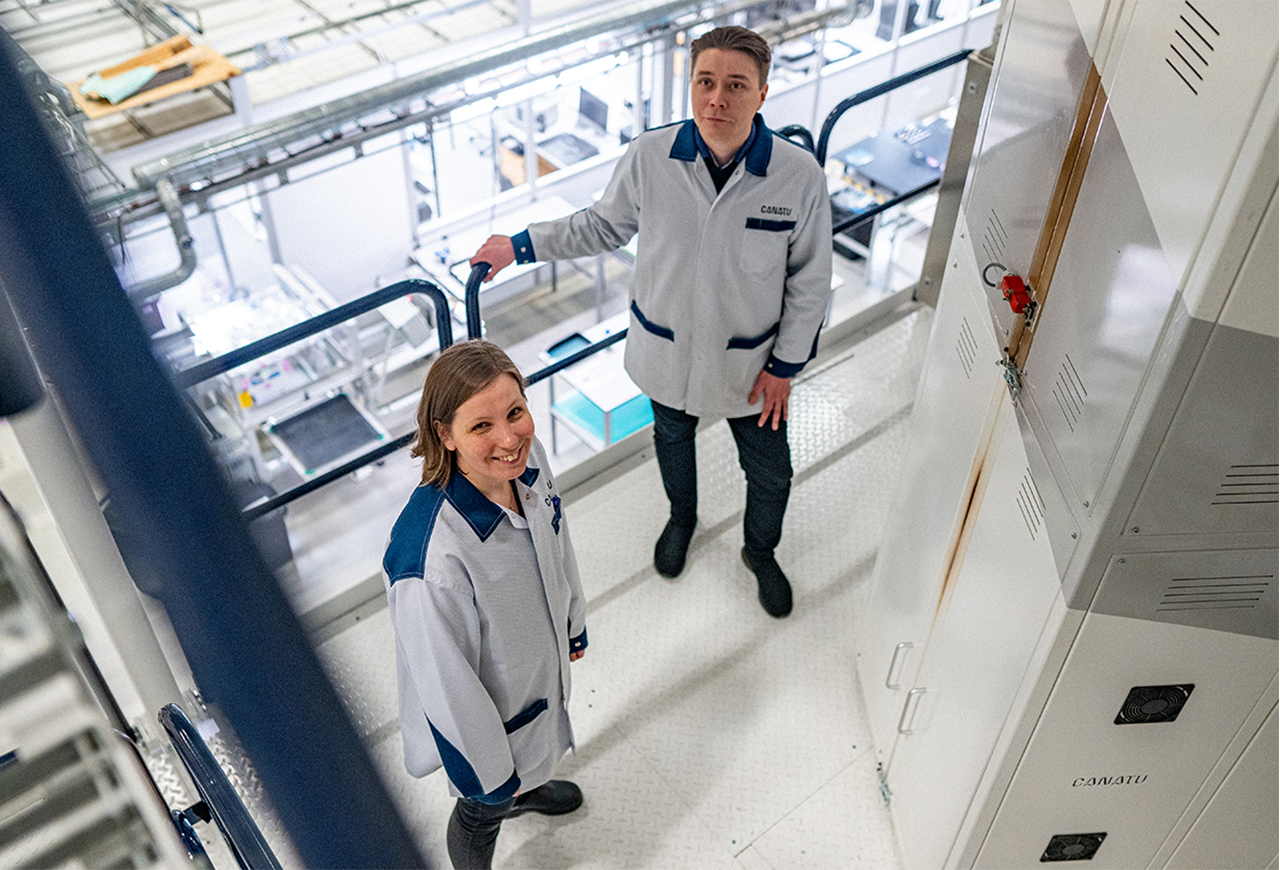

Second CNT100 SEMI reactor shipped

Canatu successfully delivered its second CNT100 SEMI reactor in December 2024 to a major global semiconductor customer. The reactor is designed for CNT pellicle membrane production.

First CNT100 SEMI reactor shipped

Canatu delivered its first customer CNT100 SEMI reactor in September 2024.

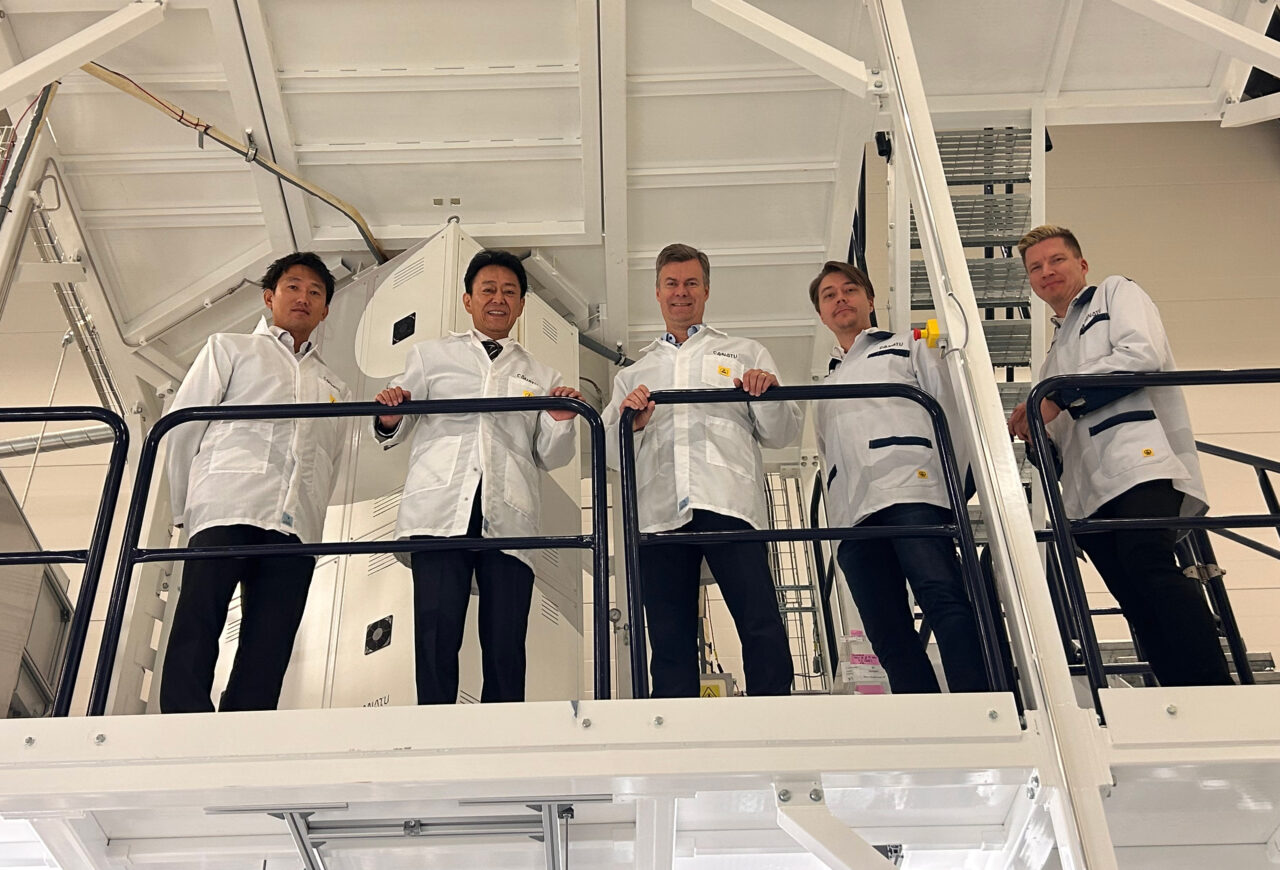

DENSO & Canatu launch CNT100 HPR

Canatu and DENSO have co-created a high-performance reactor that enhances design, process controls, and serviceability. Key upgrades, such as component upsizing and a novel parallel furnace design, boost yield. Integrated into Canatu’s automated roll-to-roll manufacturing line, these reactors enable scalable throughput, with the potential to add up to four reactors in the cluster, setting new standards for next-gen CNT film production.

The full stack is in our hands

At Canatu, we have full control over carbon nanotube production, from our unique material to our patented processes and proprietary reactors.

- Unique material: At the core of Canatu is our patented carbon nanomaterial. Canatu CNT offers exceptional properties that push the boundaries of what’s possible.

- Patented processes: our patented dry deposition process is the bedrock of our carbon nanotube production. Unlike traditional wet dispersion methods, dry deposition simplifies the process, yielding longer and cleaner CNTs, and ensuring better performance in end applications.

- Own reactors: our reactors and manufacturing equipment are meticulously designed and engineered to precise specifications. We offer a range of options, from high-performance reactors for large-scale CNT film production to specialized equipment tailored for intricate semiconductor applications.

Together, with complete control over the entire stack, we’re empowered to deliver solutions that redefine industries.

Contact our specialist in manufacturing equipment

Send us a message

Related content

Canatu’s unique process is the secret to creating the most advanced carbon nanotubes for highly-engineered products. How we make Canatu CNT yields properties that make it applicable for a variety of industry-redefining products now and in the future.

Dry deposition™ outperforms wet dispersion by simplifying the process, yielding longer and cleaner CNTs, and creating highly uniform CNT networks.

Canatu has the expertise to effectively adapt carbon nanotubes for different contexts and uses. The customizability and versatility of our synthesis process makes Canatu CNT ideal for highly engineered solutions.

We develop, create and deliver unique technology and products. Canatu CNT is used in highly engineered solutions, where precision, performance and reliability are vital.