Inspection membranes

Inspection membranes filter debris from the EUV light source and optical path, enhancing quality control in pre- and post-lithography processes.

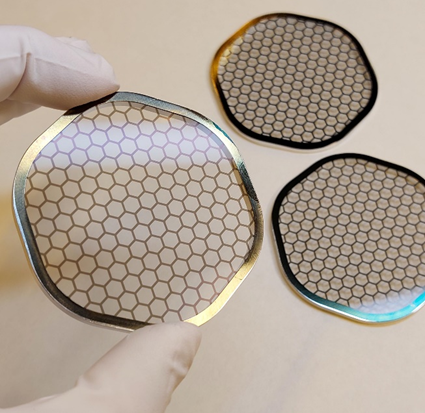

Inspection membranes with exceptional mechanical strength

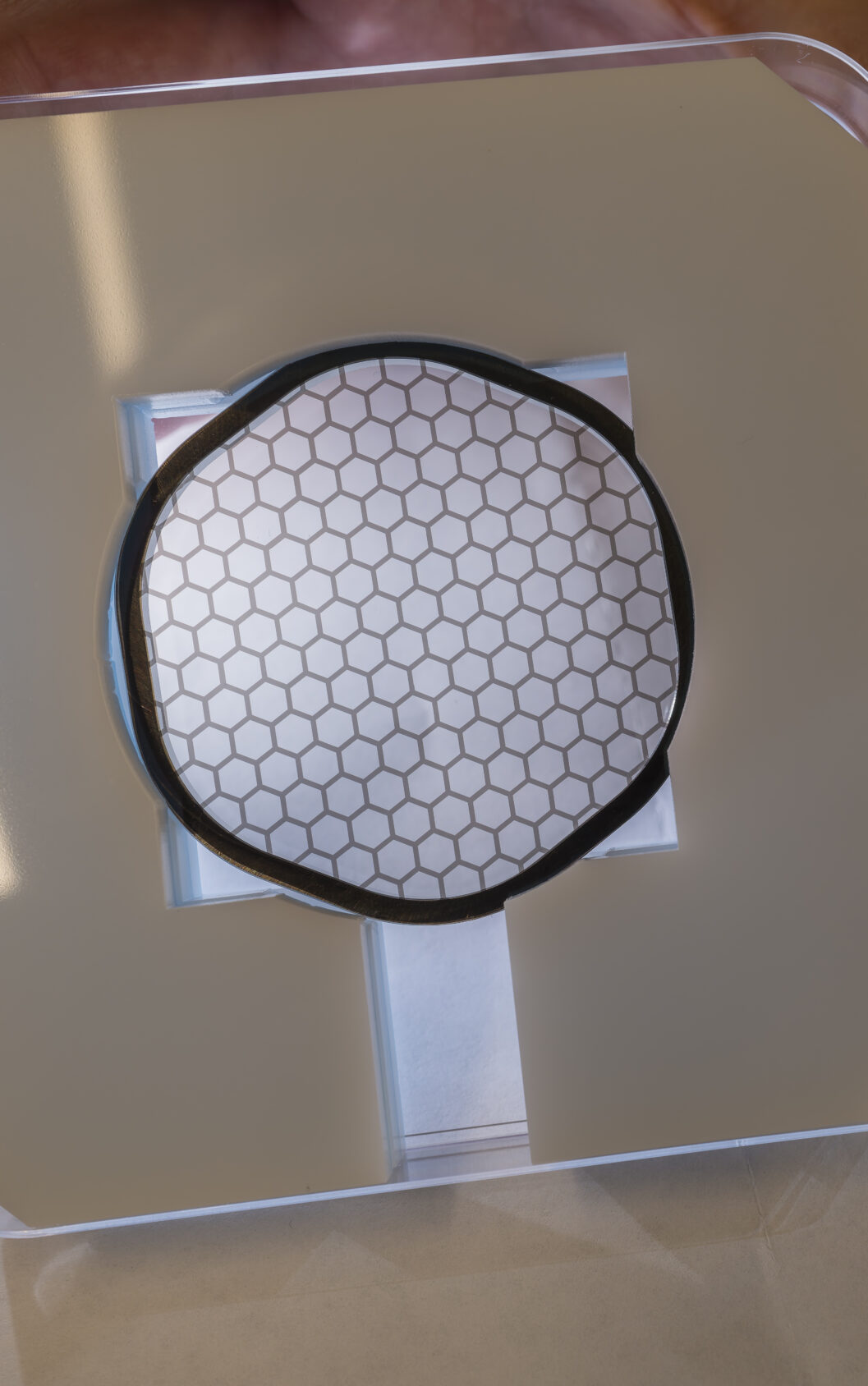

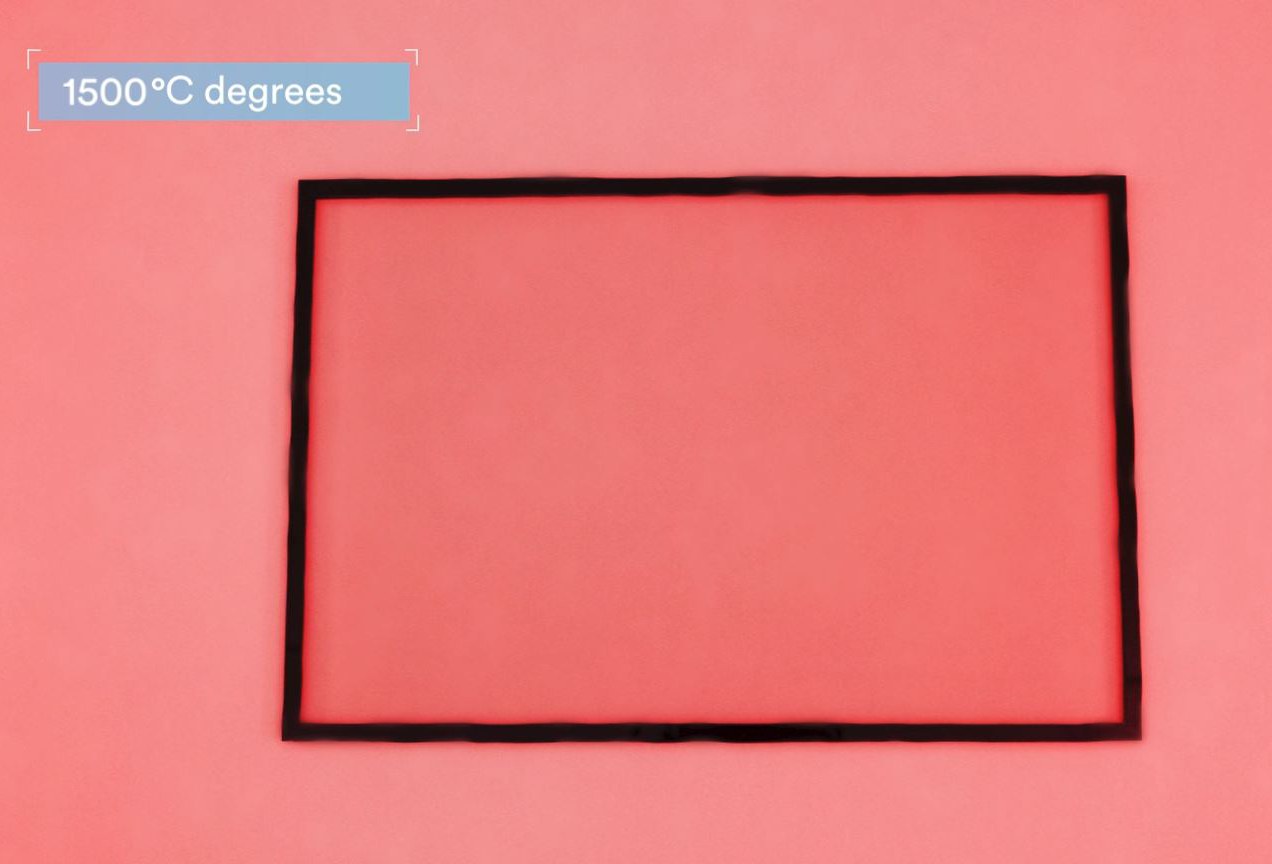

Canatu inspection membranes are designed to enhance quality control in pre- and post-lithography exposure processes. They prevent EUV-generated particles from contaminating or damaging the sensitive and expensive optics or masks, ensuring high-quality, defect-free processes with high heat resistance and EUV light transmission. In mass production since 2021, they are perfectly suited for advanced semiconductor manufacturing.

- Ultra-thin transparent debris filters with exceptional mechanical strength and long-term durability

- Withstands high-vacuum and differential pressure environments due to high tolerance to pressure pulses

- Prevents particle contamination on photomasks by filtering debris (plasma and molten metal particles) from the EUV light source and optical path

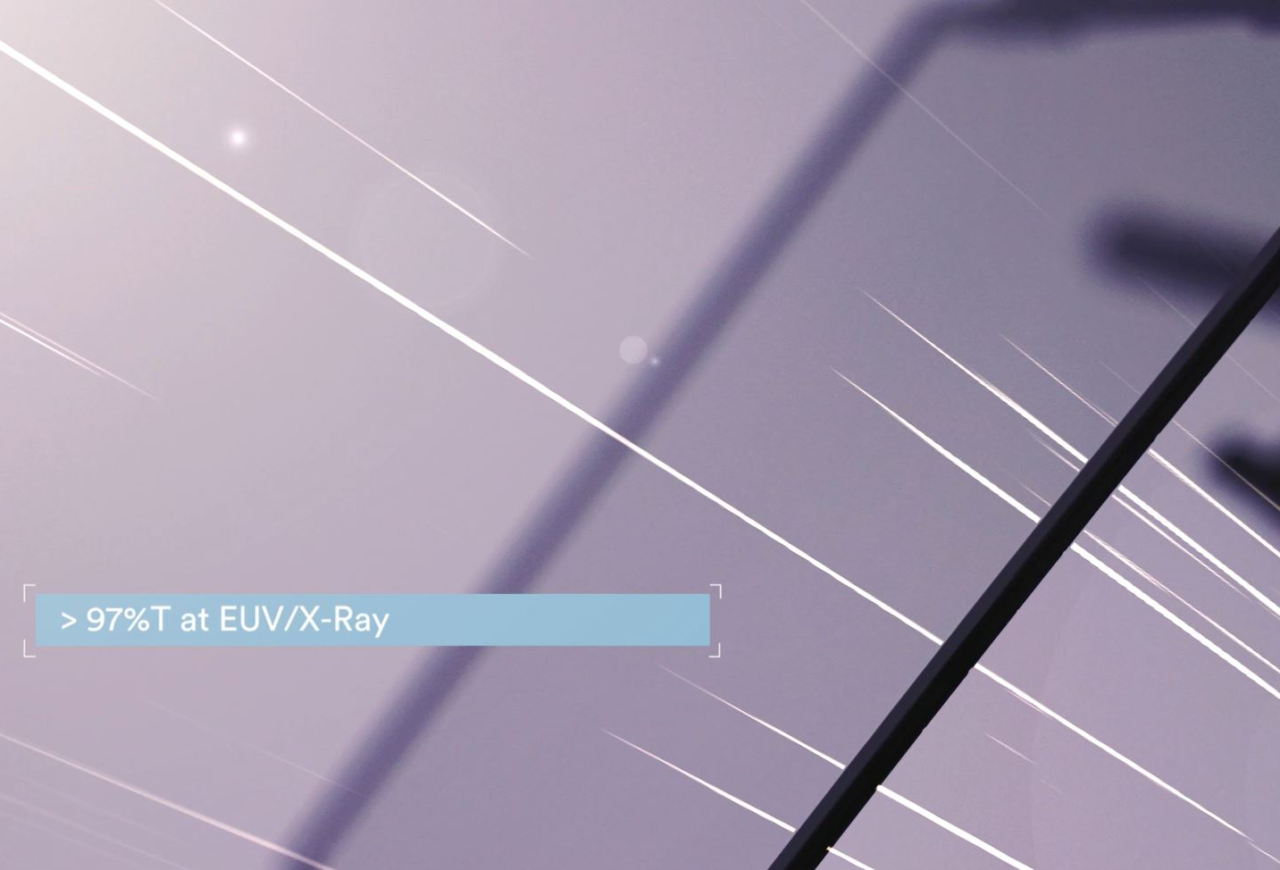

- High EUV / X-Ray transmittance while selectively blocking UV, DUV, visible, and infrared radiation for optimal light passage, enabling accurate defect detection

- Flexible fabrication onto selected frames with a novel all-carbon mesh structure

- Customizable coating thickness enabling gas sealing and differential pressure control

Download technical paper

Please download the most recent 2023 SPIE Photomask + EUVL Conference proceedings to gain deeper understanding of our versatile platform technology, unique CNT synthesis and direct dry deposition benefits, common tailoring, and potential uses for our carbon nanotube membranes.

Download technical paper

Functionality

Prevent particle contamination: Ensures contamination is minimized within the tool, including mirrors, photomask and EUV pellicle. This debris filters are utilized in EUV mask inspection to improve quality control and to protecting masks from potential contamination by the contamination source.

Preserves optical clarity of the tools: With high EUV transmittance, Canatu inspection membranes maintain optimal light passage, enabling accurate defect detection.

Application

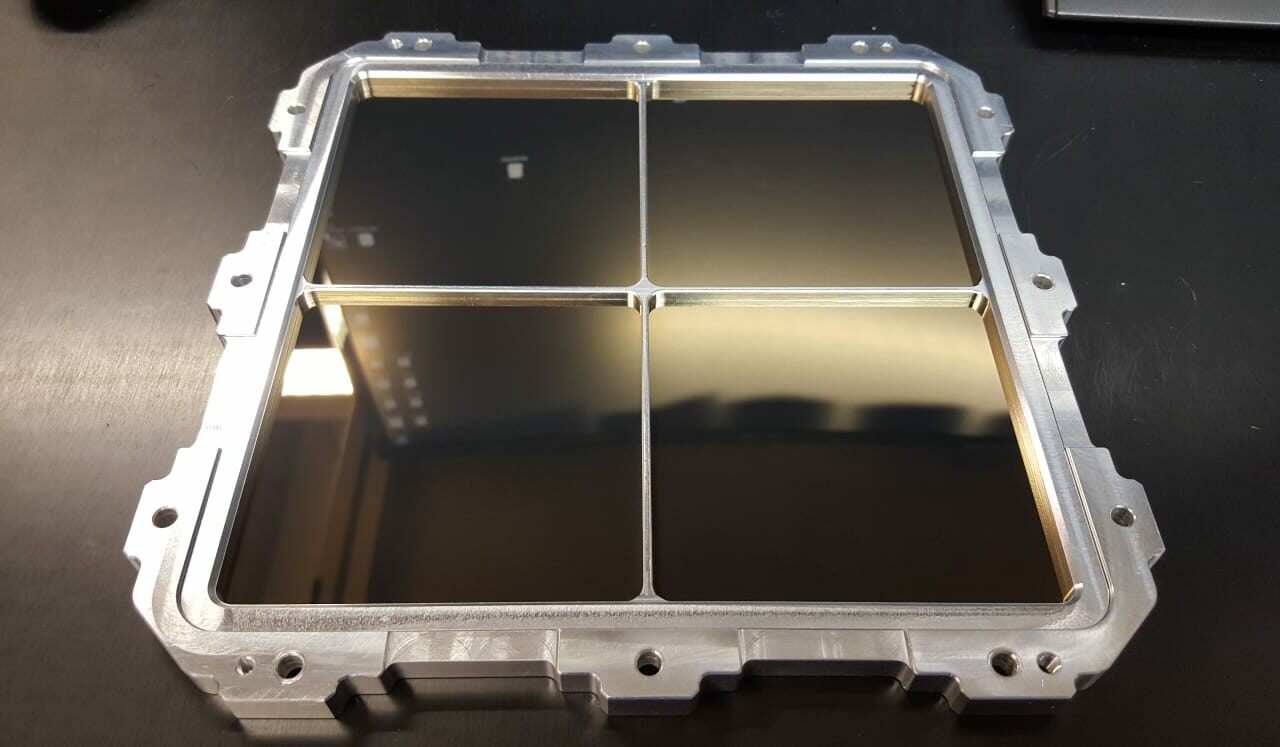

Canatu inspection membranes are used in pre- and post-lithography processes to filter debris, block DUV photons and/or electrons, and provide gas seal for differential pressure. These membranes can be used in various applications, including, but not limited to, EUV mask inspection before and after the lithography process for EUV mask qualifying tools to enhance quality control.

The patterned mask inspection is currently the primary market for Canatu’s inspection membranes. Beyond patterned mask inspection, other quality control phases – including blank masks and optical filters, are also possible applications for inspection membranes.

Key benefits

High EUV transmittance: Ensures optimal light passage for accurate defect detection

Flawless mask inspection: Prevents contamination from EUV light source and optical path, ensuring defect-free mask

Extended lifespan: Enables lower inspection machine power usage, extending the laser source’s lifespan and reducing service interval.

Leveraging versatile platform technology for X-Ray optical filters

Canatu CNT membranes serve as a versatile platform technology for a wide range of EUV and optical filter applications. Within Canatu’s product portfolio, you will find an array of cutting-edge solutions such as CNT pellicle membranes, inspection membranes, and optical filters tailored to different needs.

These membranes are created from Canatu CNT, renowned for its exceptional purity and properties. Canatu CNTs are synthesized in a floating catalyst chemical vapor deposition (FC-CVD) reactor, and then dry-deposited onto an open frame or a border. With more than a decade of experience in large-scale production of CNTs, Canatu excels in controlling the process and tailoring CNTs for different uses.

All-carbon mesh

A novel mesh structure manufactured from Canatu CNTs provides an alternative to conventional metal meshes.

- Enhanced mechanical properties

- Excellent film-to-mesh adhesion

- Stops film tear propagation after puncture

- A wide range of shapes and dimensions to minimize EUV transmittance loss

- Retains spectral purity in X-ray applications

Contact our specialist in inspection membranes

Send us a message

Related content

Bespoke membrane solutions for your exact needs. Applicable for high-power EUV lithography and optical filter applications. Made of the most advanced carbon nanotubes, known for their exceptional purity and properties. Learn more.

Canatu CNT membranes are well suited for use in X-Ray filter applications because of their high X-Ray transmittance, resistance to pressure differentials, and chemical inertness. These X-Ray filters can be placed e.g. in front of an X-Ray detector to block particles, electrons, and photons that fall outside the desired energy range, while providing high X-Ray transmittance and enduring high temperatures & differential pressure conditions. Discover the product.

Semiconductors are all around us in every single electronic device we use. That is how they make an impact in our everyday. Progress in the semiconductor industry continues fast driven by Moore’s Law. Canatu CNT plays a role in enabling breakthroughs in the rapidly changing semiconductor industry. See more.

Our unique expertise is how we adapt CNT to different contexts and uses. The extensive customizability and versatility of Canatu CNT synthesis process allows us to create the most advanced carbon nanotubes for highly engineered solutions. Discover more.

Canatu CTO Ilkka Varjos presented free-standing CNT membrane platform technology at SPIE Photomask + EUVL 2021. His talk focused on the unique qualities of Canatu CNT, extensive customizability of the CNT synthesis and post-processing, and application potentials. See press release.