Single walled carbon nanotubes vs. multi walled carbon nanotubes

Carbon is the most versatile material in the universe. Over the years, Canatu has developed its expertise in adapting and modifying aspects of our superior carbon nanotubes to suit different contexts and applications. Canatu achieves this elevated level of customization through various synthesis processes.

One key alteration that can be made is to dictate the number of walls each nanotube has, e.g. producing single walled carbon nanotubes (SWCNTs), double walled carbon nanotubes (DWCNTs), or multiple walled carbon nanotubes (MWCNTs).

Different applications require different wall types due to their varied properties. For instance, in practice only single walled carbon nanotubes can be utilized as semiconductors such as transistors. Single walled carbon nanotubes can also benefit electrochemical sensors due to their large surface area that enables extremely high sensitivity.

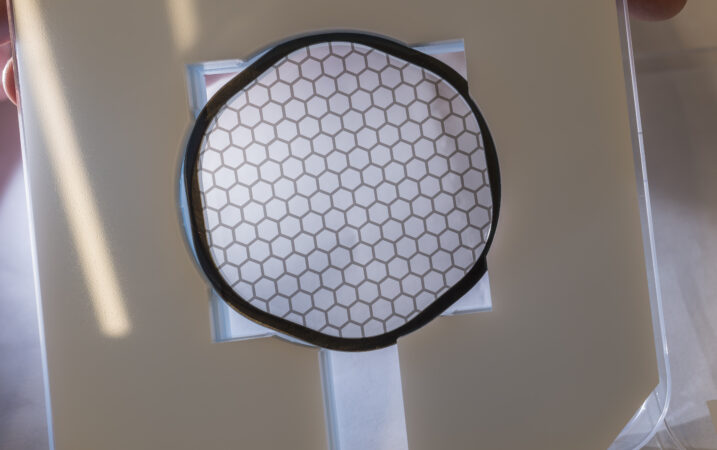

On the other hand, multi walled carbon nanotubes are remarkably stronger than the already impressively strong single walled carbon nanotubes. They are suitable for harsh chemical environments, automotive and other applications that require high mechanical stress such as filtration membranes.

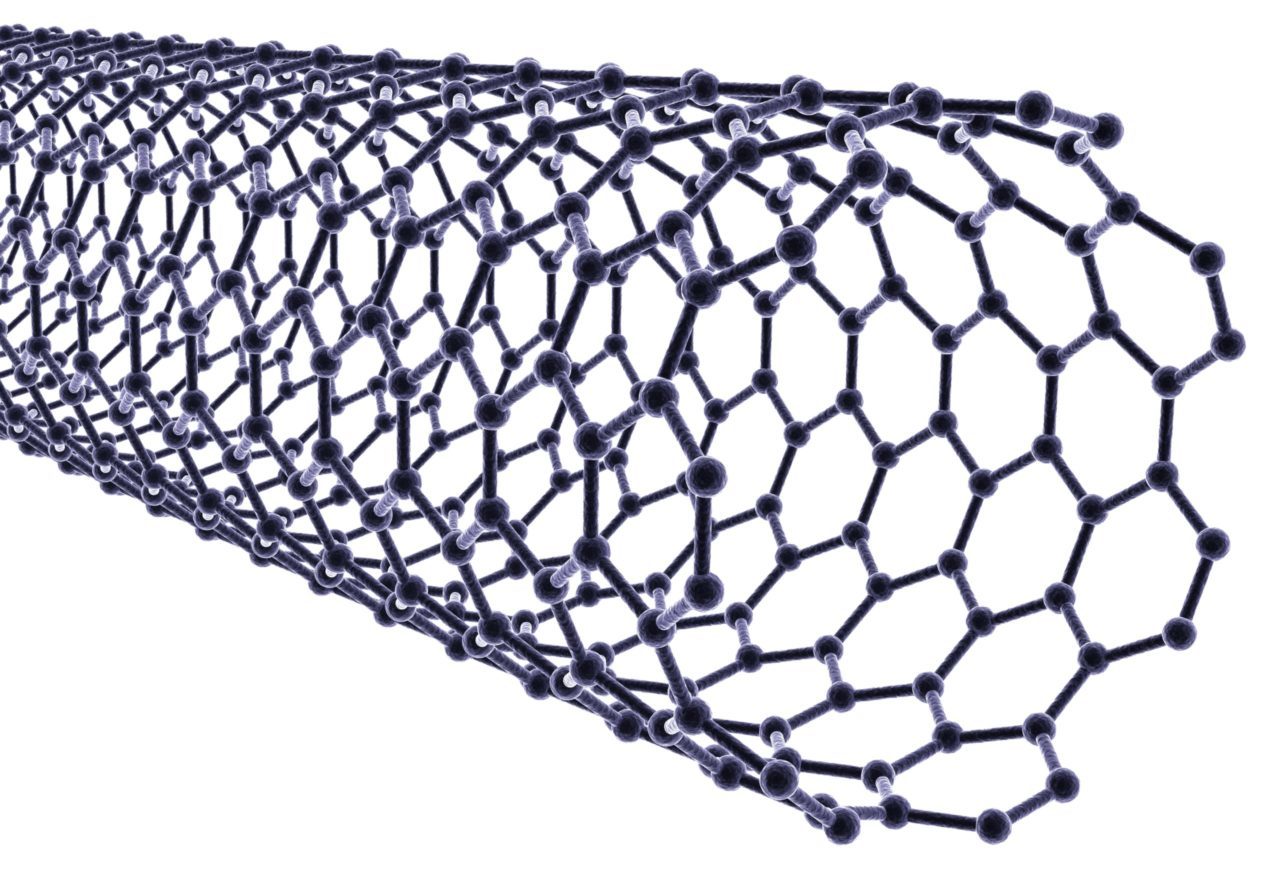

Single walled carbon nanotubes

Single walled carbon nanotubes are cylinders consisting of only one layer of graphene.

Single walled carbon nanotubes exhibit unique electronic properties which can change significantly depending on their chiral vector. Due to this property, single walled carbon nanotubes are commonly utilized as semiconductors, such as in transistor applications.

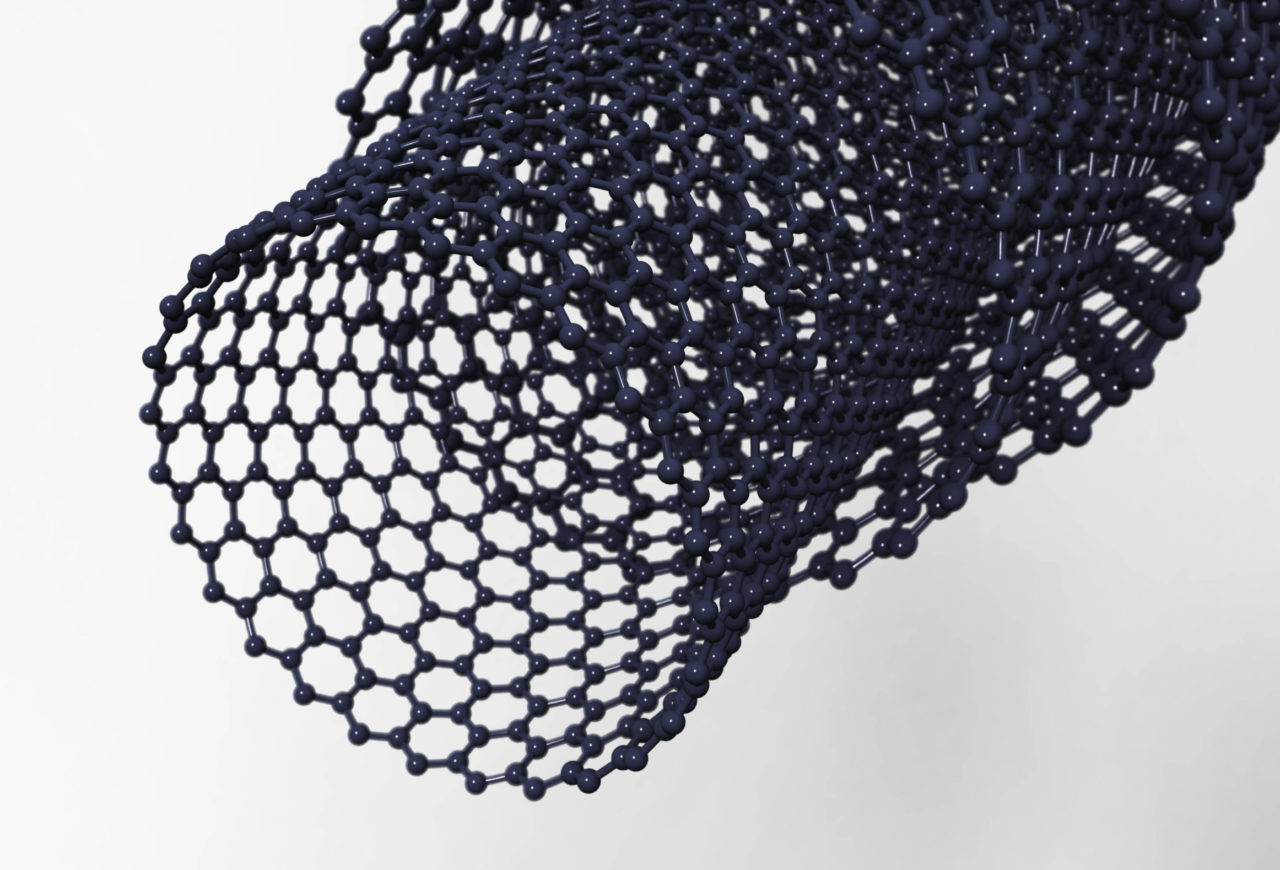

Multi walled carbon nanotubes

Multi walled carbon nanotubes are cylindrical with concentric, multiple layers of graphene. They are longer in diameter, have a higher aspect ratio and are remarkably stronger than the already strong single walled carbon nanotubes.

In practice, multi walled carbon nanotubes are used in applications that require high mechanical strength.

Modifying carbon nanotubes and their properties

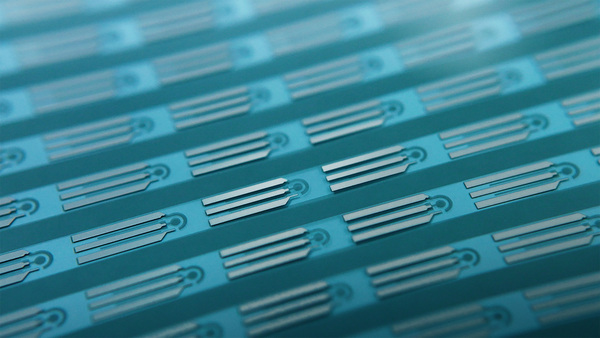

When synthesized using Canatu’s Floating Catalyst Chemical Vapor Deposition (FC-CVD) method, carbon nanotubes can be customized to have a different number of side walls or a desired mix of them.

The CNT synthesis process essentially changes the properties of the carbon network, drastically opening a realm of new opportunities.

For example, in the context of manufacturing free-standing CNT membranes, one can break the outer cells while keeping the inner tubes intact. This allows the addition of different molecular complexes and that can be bonded to the outer cells, effectively changing the properties of the membrane. On the other hand, leaving the inner tubes intact preserves the membrane’s high electrical conductivity and mechanical strength.

Contact our specialist in carbon nanotubes

Send us a message

Related content

Canatu has the best process to create the most advanced carbon nanotubes for highly engineered solutions. Carbon nanotube manufacturing at Canatu is done using Floating Catalyst Chemical Vapor Deposition process. This process provides better control over CNT growth compared to the traditional approach. More about manufacturing.

In our unique dry deposition process, the carbon nanotubes are nucleated in a reactor, and deposited onto a substrate directly underneath the reactor. This results in cleaner, longer, less defective CNTs which lead to more enhanced properties and increased performance across different applications. Discover differences.

Canatu has the expertise to effectively adapt carbon nanotubes for different contexts and uses. The customizability and versatility of our synthesis process allows us to create the most advanced CNTs for highly engineered solutions. Read about variants.

Carbon nanotubes have unique mechanical, electrical, thermal, optical, and chemical properties. CNTs have very high tensile strength, high thermal and electrical conductivity, they are highly flexible and very elastic. Discover CNT properties.