Sustainability

We are all about making things future-proof. Whether working with partners on new solutions or developing our operations, a more sustainable future guides our actions. To minimize our environmental impact, we focus on four strategic areas.

We support our customers in achieving their ESG targets. The foundation for our sustainability and ESG initiatives was laid in 2020 with the creation of Canatu’s environmental strategy. At the core of this strategy are four key goals designed to enhancing the sustainability of our carbon nanotube (CNT) manufacturing. To guide us in minimizing the environmental impact, we have set a clear roadmap including measures for emission avoidance, reduction, and offsetting. We aim at carbon neutral own operations by 2035. Let’s dive deeper into our four strategic goals.

Cut electricity consumption

Our goal was to reduce electrical consumption to a fifth per production unit (m2 of CNT film). The most efficient way to achieving this is by accelerating our CNT synthesis through the deployment of a next-generation, high-performance reactor. The goal was achieved by the end of 2023.

Reduce CO2eqv air emissions

Next, our goal is to reduce CO2-equivalent air emissions to a fifth per production unit (CNT film m2) by the end of 2025. Air emissions can be substantially cut by implementing new high-performance reactors. Between 2021 and 2022, we decreased CO2eqv emissions by 58% per square meter of CNT film manufactured, as compared to our earlier reactor models. We also seek to implement a heat exchange system to recover heat from our process, and continuously improve our process chemistry to enhance sustainability.

Reduce carbon emissions from process exhaust

Our goal is to achieve substantial reduction in carbon emissions from process exhaust by the end of 2026. We seek to implement carbon emission scrubbers into our exhaust lines, with the aim of reducing greenhouse gases, such as carbon monoxide or methane, from the process exhaust.

Carbon neutral own operations by 2035

We have raised our own ambition and aim at carbon neutral own operations by 2035. We have made great progress towards our environmental goals. Our factory is 100% powered with renewable electricity.

Operating in alignment with third-party international standards

Canatu has received the IATF 16949 certification, the international quality management standard for the automotive industry. The IATF 16949 certification further solidifies our role in the automotive industry as a company that can transform the driving experience for a safer, more comfortable and reliable future. It is a confirmation for our high quality and large-scale mass production capabilities, which have been at the service of the automotive industry since 2015. Through the years we have refined our process which is fine-tuned to ensure consistent quality. The IATF 16949 certification has been implemented as an extension and in combination with ISO 9001. Canatu also holds ISO 14001 certification. Download certificates:

IATF 16949:2016

ISO 14001:2015

ISO 9001:2015

EcoVadis Bronze:2024

Canatu has been awarded a Bronze Medal by EcoVadis on social responsibility. This places us in the top 35% among all evaluated companies world-wide.

Are carbon nanotubes sustainable?

Carbon nanotubes have the potential to enable several cleantech solutions offering higher performance and lower footprint compared to traditional materials. Three main arguments for the sustainability of carbon nanotubes are their superiority over alternative materials, production methods, and the potential to enable green technologies.

In comparison to other conductive carbon materials like carbon black and graphene, carbon nanotubes are relatively sustainable. For instance, carbon black has higher CO2 footprint per kg than graphene and carbon nanotubes.

Second, the production process of graphene has significant challenges including energy inefficiency, high water usage, and the use of harsh chemicals. Canatu, on the other hand, deploys chemical vapor deposition (CVD) method for synthesizing carbon nanotubes. Our direct dry deposition method does not involve any harmful chemicals for the environment.

Another emerging aspect in carbon nanotube manufacturing is using waste or by-product methane as feedstock, effectively trapping carbon emissions into a physical form instead of releasing greenhouse gases.

Towards the end of the value chain, carbon nanotubes hold high potential to enable several cleantech technologies. Application areas like membranes, film heaters and electronics all are driven by sustainable goals and exploring CNT-based solutions. At Canatu, our focus is purely on highly-engineered solutions, where carbon nanotubes have a major role.

When we look at the whole value chain, from comparing alternative materials to production processes and applications, carbon nanotubes emerge as a sustainable material that enable next-generation sustainable products. (Source: IDTechEx, PEN)

Contact

Send us a message

Related content

Canatu participates in a 40M€ EU flagship project to propel electronics industry towards circular economy, bio-based materials, eco-design, and material- and energy-efficient manufacturing processes. Within the Sustronics project, Canatu plans to create a sustainable biosensor for C-peptide, which is a biomarker, e.g. for an early-stage diabetes diagnosis. Read press release.

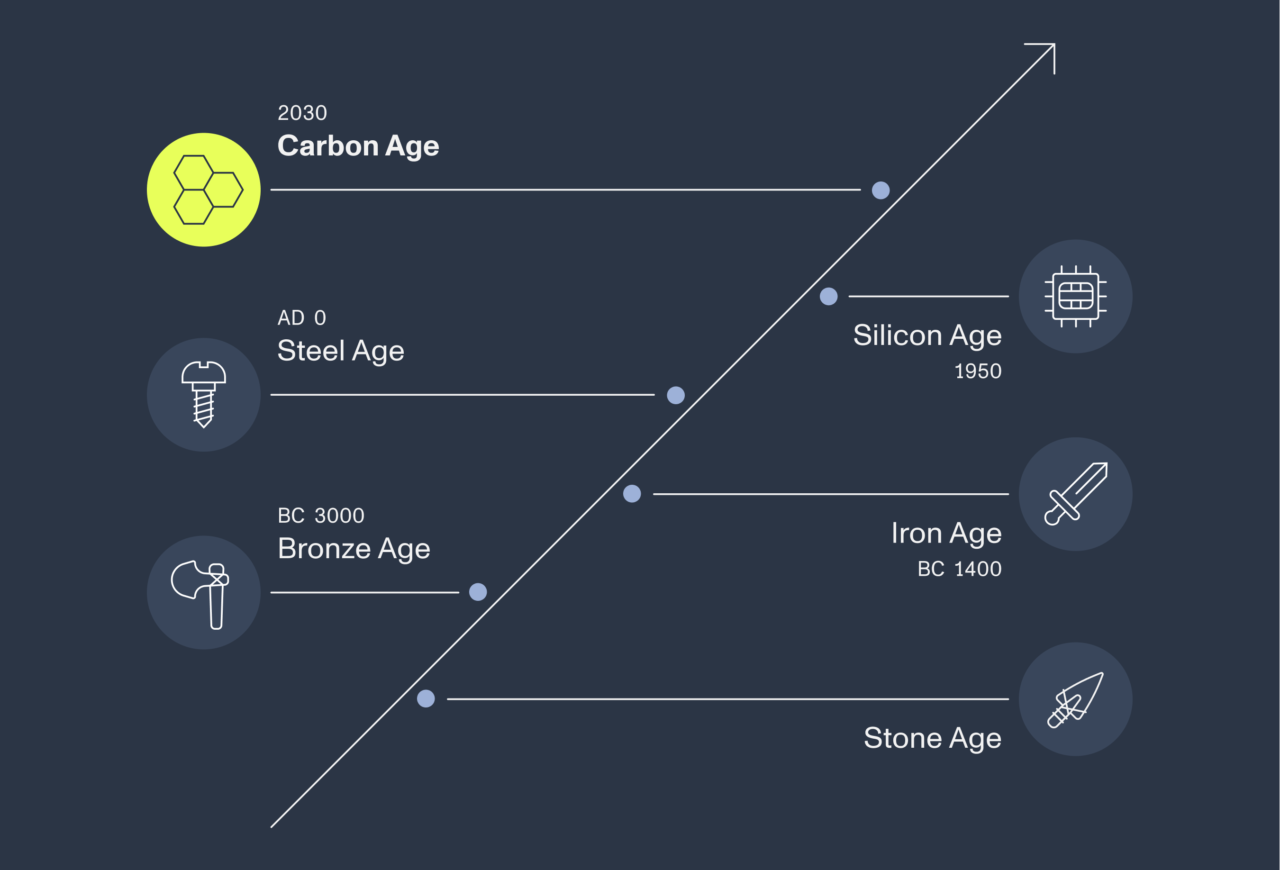

Carbon nanotubes have the potential to enable several cleantech solutions, delivering higher performance and a lower carbon footprint. Utilizing carbon as a building block instead of releasing it into the climate is the foundation of the Carbon Age. Read story.

The UN Global Compact is the world’s largest corporate sustainability initiative, with the goal of harmonizing operations according to ten principles covering human rights, labor, environment, and anti-corruption. See news.

Carbon is versatile, future-proof and available everywhere. With nanotech we extract the unique properties of carbon, making it attractive across different applications. Learn how breakthroughs can be enabled with more responsible materials and smaller quantities for massive impact. Learn more.

Canatu has been awarded a Bronze Medal by EcoVadis on social responsibility. This places us in the top 35% among all evaluated companies world-wide. The assessment focuses on 21 sustainability criteria that are grouped into four themes: environment, labor & human rights, ethics, and sustainable procurement.

Canatu has received the IATF 16949:2016 certification for its manufacturing facility in Vantaa. The IATF standard takes into account performance over multiple themes including customer requirements, production management and systematic quality thinking. See press release.

Canatu has been awarded with the Silver level rating by the global sustainability rating platform EcoVadis. With a total score of 64 points out of 100, this puts Canatu among the top 25% of companies in the world assessed by EcoVadis, and well above the industry average of 44. See news release.

Canatu has shifted from fossil fuels to renewable energy part of our sustainability strategy to decarbonize production by 2035. This transition is primed to reduce our CO2 emissions from electricity staggering 94%, while reducing our total CO2 emissions by 60%. See news release.

Canatu creates nano solutions for massive impact. We work with carbon, the most versatile material in the universe, and collaborate with other forerunner companies to make breakthrough innovations. Get to know Canatu.

Canatu’s unique process is the secret to creating the most advanced carbon nanotubes for highly-engineered products. How we make Canatu CNT yields properties that make it applicable for a variety of industry-redefining products now and in the future. Our process opened up.

Our main focus today is on the automotive and semiconductor industries. We continuously expand what is possible with nano carbon, searching for new opportunities. Work with Canatu CNT.