Semiconductor

Enabling the next step in efficiency

Semiconductors are all around us in every single electronic device we use. That is how they make an impact in our everyday. Progress in the semiconductor industry continues fast driven by Moore’s Law aimed at doubling the transistor density on a wafer every two years. Higher transistor density will lead to more efficient processors and memory chips for the benefit of everyone using electronic devices.

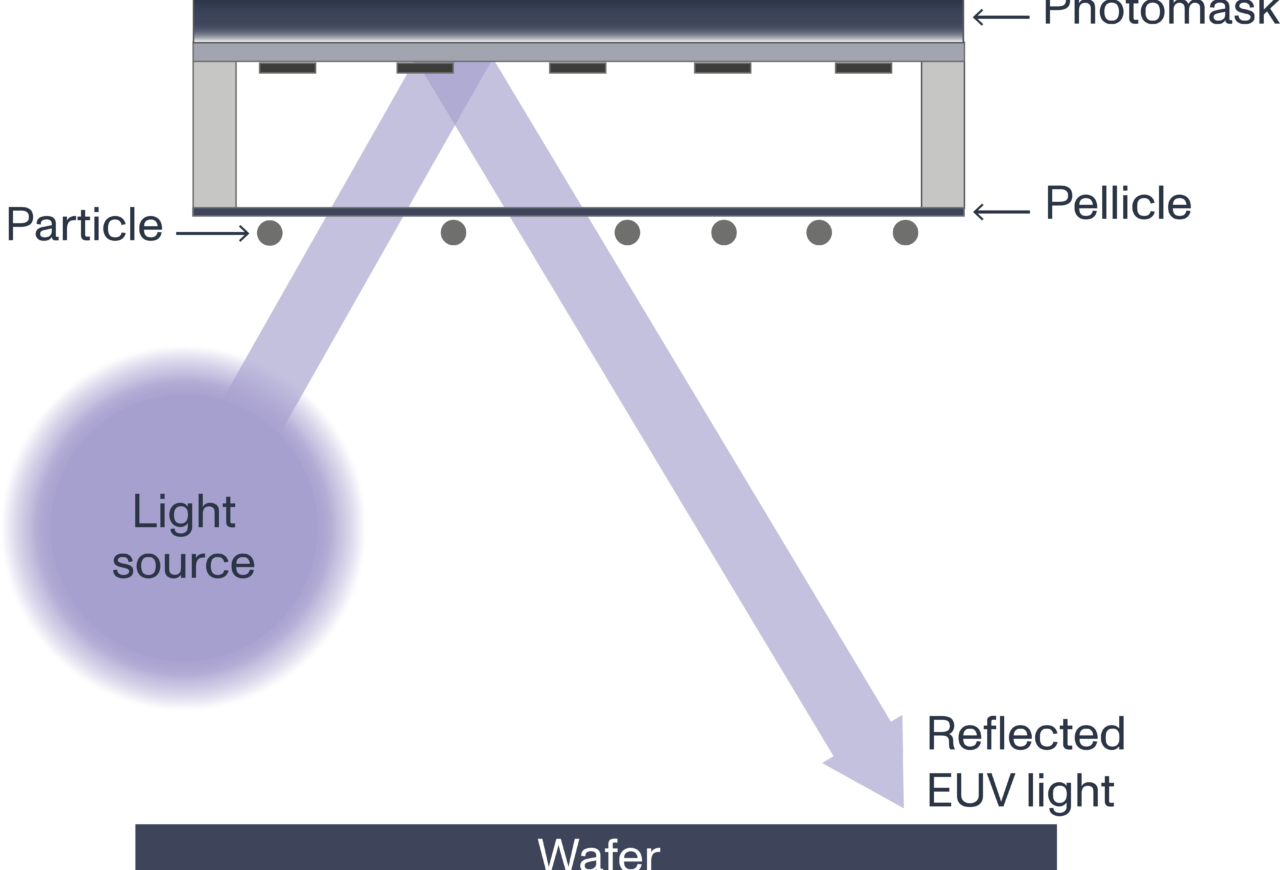

To keep up with the pace of development, the industry has developed extreme ultraviolet lithography (EUV) technology. Using extreme ultraviolet wavelengths, this wafer exposure technology improves resolution and allows producing wafers with transistor node sizes of 7 nm or less.

Canatu CNT plays a key role in advancing the EUV process required for producing the most advanced microchips. Today, Canatu is a prominent supplier of CNT -based products and manufacturing equipment for the semiconductor industry. Our product portfolio includes CNT pellicle membranes, inspection membranes, and optical filters for EUV and X-ray filter applications.

Our products

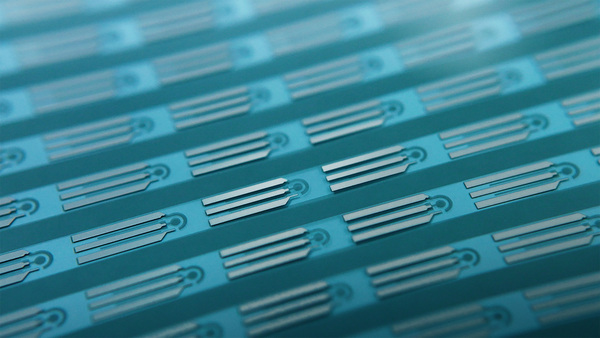

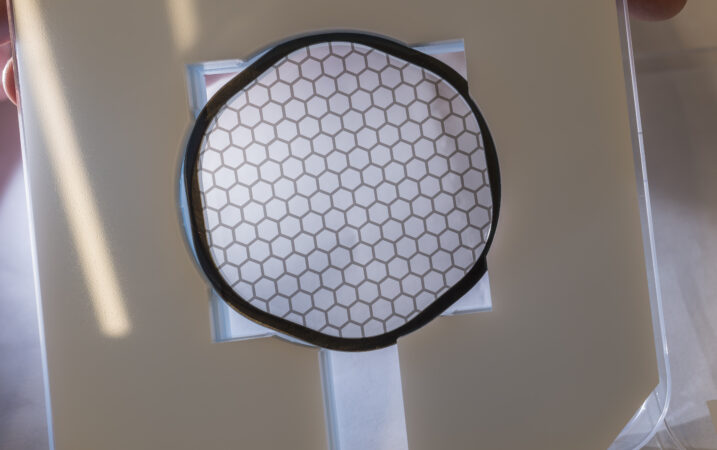

The world’s thinnest and strongest carbon nanotube membranes, tailorable for your exact needs. Applicable for high-power EUV lithography and X-Ray filter applications. Made of the most advanced carbon nanotubes, known for their exceptional purity and properties.

CNT pellicle membranes are used to protect the photomask from contamination while permitting high EUV transmission. Canatu CNT pellicle membranes support the productivity increase potential in the EUV lithography process by up to 8-15%.

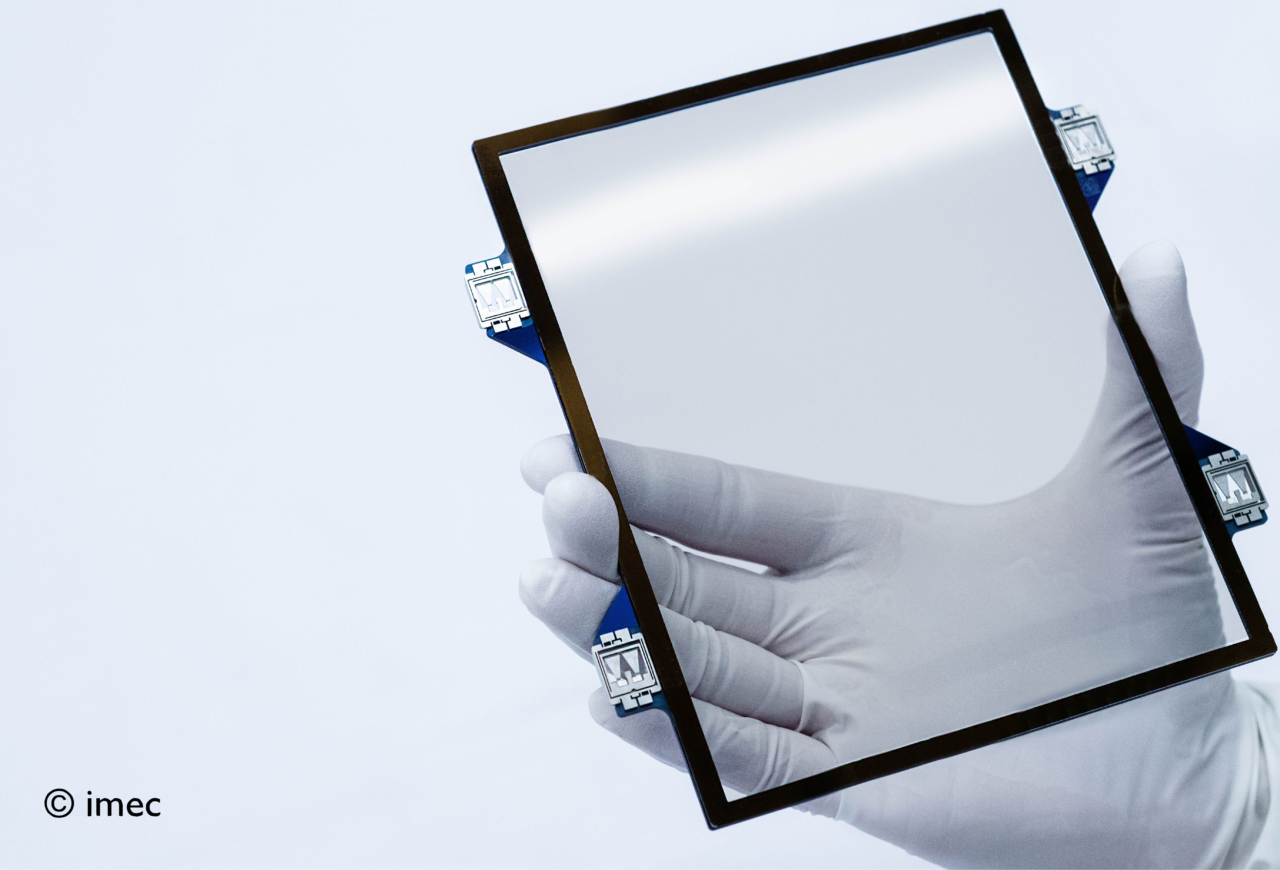

Canatu optical filters block short-wavelength photons and high-energy particles that can interfere with the measurement process, while providing high transmittance for EUV and X-ray wavelengths.

Canatu inspection membranes enhance quality control by filtering debris from the EUV light source and optical path, preventing particle contamination on photomasks. They feature high EUV transmittance for optimal light passage, enabling accurate defect detection. These membranes are utilized at various inspection stages, including mask manufacturing and pre- and post-lithography processes. They can allow lower power consumption for the inspection machine, extend the laser source’s lifespan, and reduce service intervals.

Taking semiconductors to a smaller scale

As volumes rise in semiconductor manufacturing and ever-smaller features are printed on them, there is greater pressure to avoid defects. Tiny defects lead to errors on the wafer, causing costly yield losses.

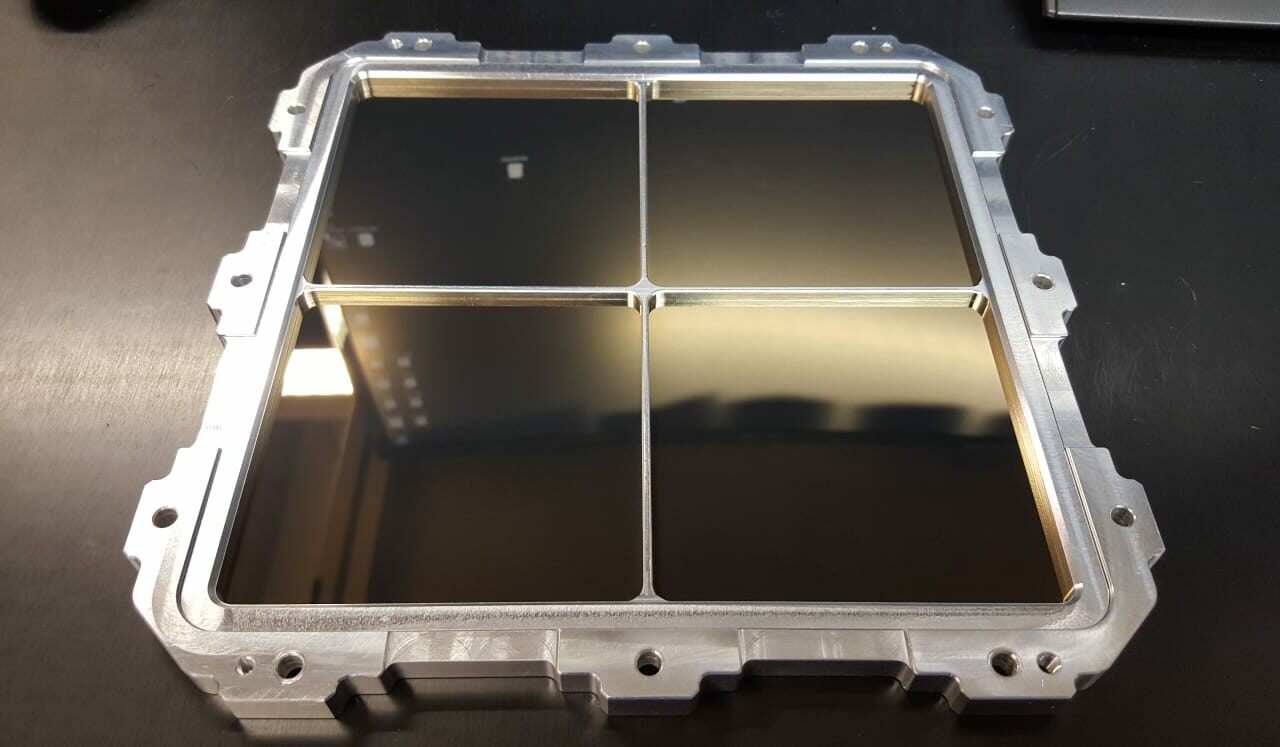

Canatu has a unique solution based on CNT membrane to enable nanoscale debris filtering in a demanding environment: high EUV transmittance, low reflection and flare, high heat resistance and mechanical strength.

EUV pellicles are membranes that protect the photomask from particle contamination while permitting EUV transmission. The CNT membrane must be thin enough to limit the imaging impact while robust enough to survive handling.

See video

Contact our specialist in semiconductors

Send us a message

Related content

The next-gen EUV scanner will introduce high power levels of over 500W, enabling the next step in efficiency. Higher power levels and reticle acceleration cause high heat loads and mechanical stress on the EUV pellicles. Carbon nanotubes have emerged as the most promising material for EUV pellicles used in high power EUV scanners due to their mechanical and thermal properties. See article.

The discovery of new things is deep in Canatu’s DNA. From the beginning, we have explored uncharted territory with curiosity. While our experts solve the issues of today, they are also working on what’s to come. To future developments.

Canatu’s manufacturing platform produces high-quality, free-standing CNT membranes in various sizes, shapes, and carbon nanotube structures. This gives Canatu the ability to adjust the free-standing CNT membrane properties to best meet the end application needs, and to quickly scale up to mass production from the initial prototyping phase. See the platform.

Semiconductors impact our everyday life through every single electronic device we use. Canatu CTO Ilkka Varjos expounds on how Canatu can help improve yield and throughput of high-volume semiconductor manufacturing with EUV membranes made of Canatu CNT. See article.

Canatu presented on free-standing CNT membrane technology at the SPIE Photomask and EUVL Digital Forum, focusing on the unique qualities of the platform, the extensive customizability of the CNT synthesis and post-processing, and application potentials for the free-standing CNT EUV membranes in semiconductor manufacturing and beyond. See press release.

Canatu creates nano solutions for massive impact. We work with carbon, the most versatile material in the universe, and collaborate with other forerunner companies to make breakthrough innovations. See our company.

Canatu CNT’s qualities excel in automotive applications, where high optical, electrical and mechanical properties are of utmost importance. Canatu supports the automotive industry in enabling increased safety, comfort and autonomy in driving. See more.

EUV pellicles made of Canatu CNT are critical enablers of high yield and throughput in high-volume semiconductor manufacturing, offering unique benefits that are unparalleled by other materials. See the product.

Canatu creates the most advanced carbon nanotubes well-suited for transformative solutions, where precision and reliability are essential. See our products.