EUV pellicles

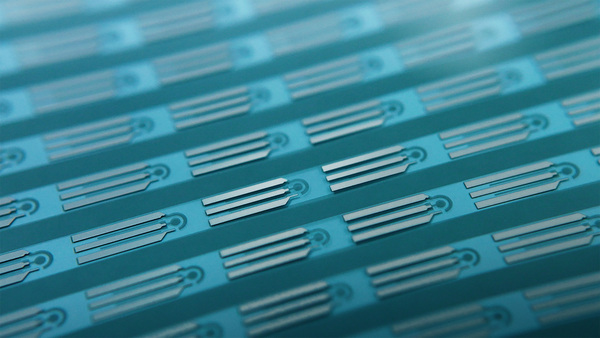

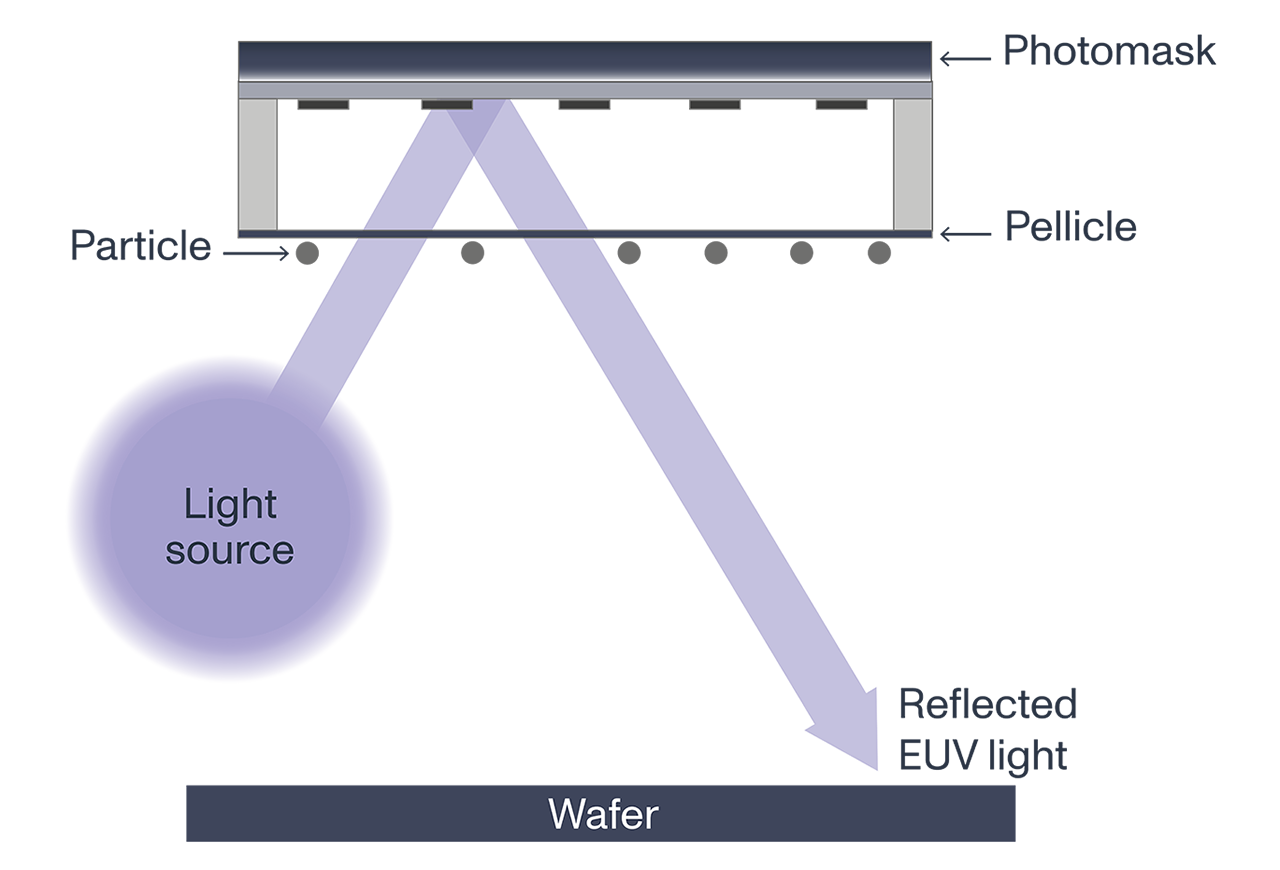

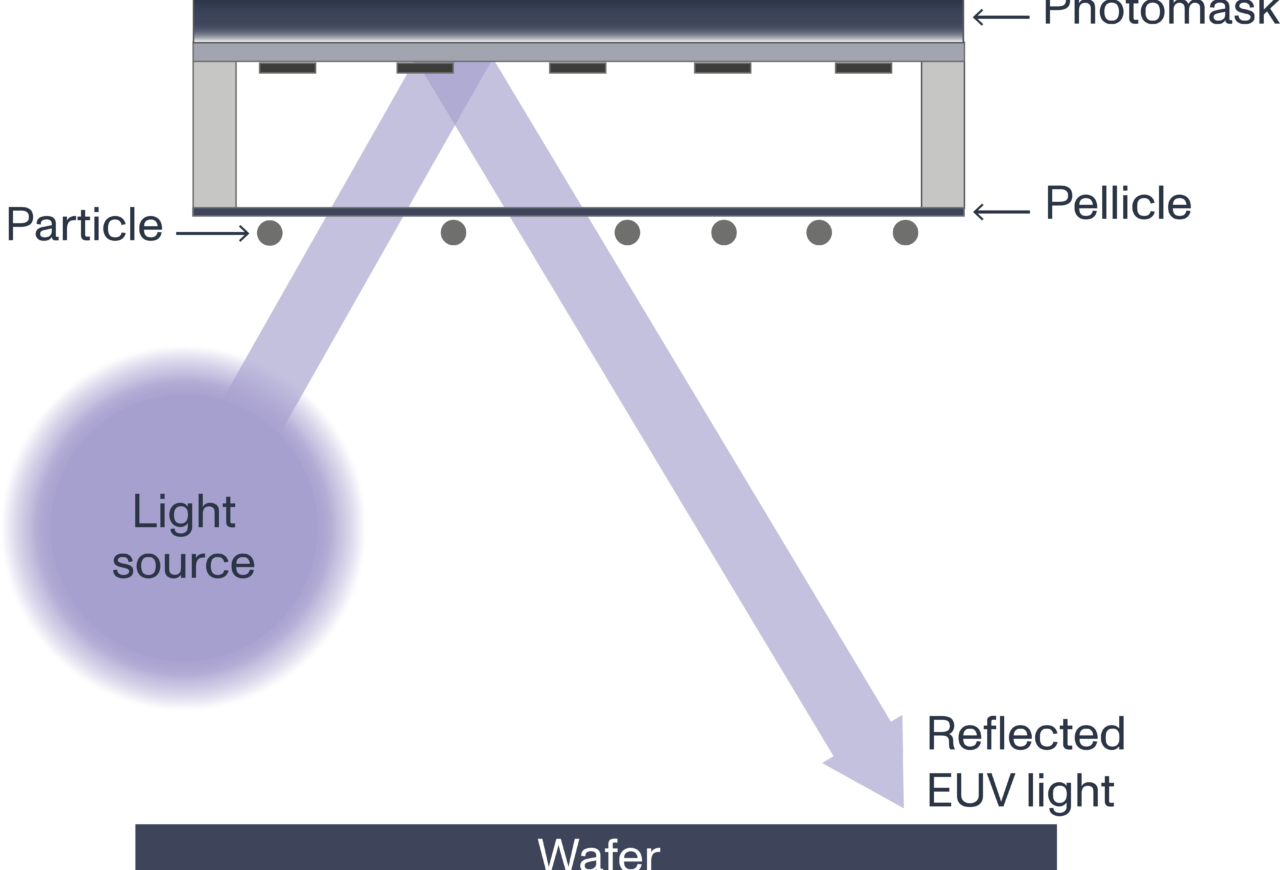

EUV pellicles are membranes used to protect the photomask from contamination while permitting high EUV transmission. EUV pellicles made of Canatu CNT offer unique benefits unparalleled by other materials.

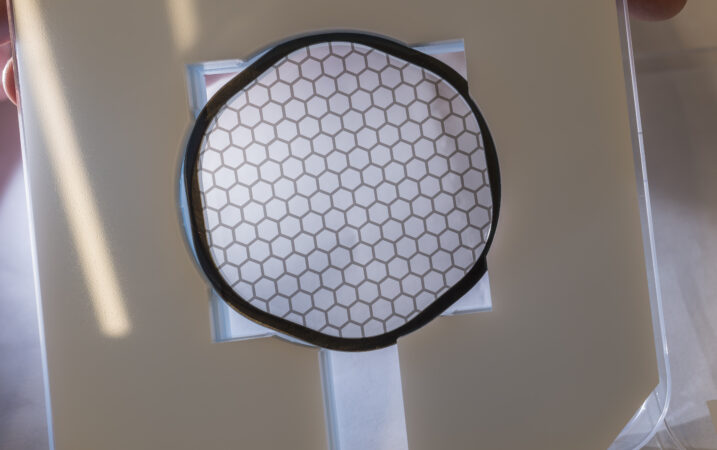

CNT pellicle membranes protect the photomask from defects during EUV lithography

The semiconductor industry is experiencing growing demand for advanced chips, driven by advancements in artificial intelligence (AI) and computing, with sub-7nm chips made using the EUV technology growing the fastest. The next generation high-power EUV lithography machines operating at >500W require EUV pellicles to protect photomasks from particle contamination during chip production. Traditional materials struggle to withstand higher heat loads and mechanical stress of the more advanced EUVL machines, leading to performance issues. Canatu CNT pellicle membranes have the potential to outperform conventional composite pellicles in handling the higher heat loads and mechanical stresses of next-generation EUV lithography machines. Canatu CNT pellicle membranes support the productivity increase potential in the EUV lithography process by up to 8-15%.

Key properties:

- High EUV transmission

- High thermal stability up to 1500°C in vacuum

- Exceptional strength

- High uniformity

CNT is the material choice for EUV pellicles

The next-gen EUV scanner will introduce high power levels of over 500W, enabling the next step in efficiency. Higher power levels and reticle acceleration cause high heat loads and mechanical stress on the EUV pellicles. Carbon nanotubes have emerged as the most promising material for EUV pellicles used in high power EUVL machines due to their optical, mechanical and thermal properties

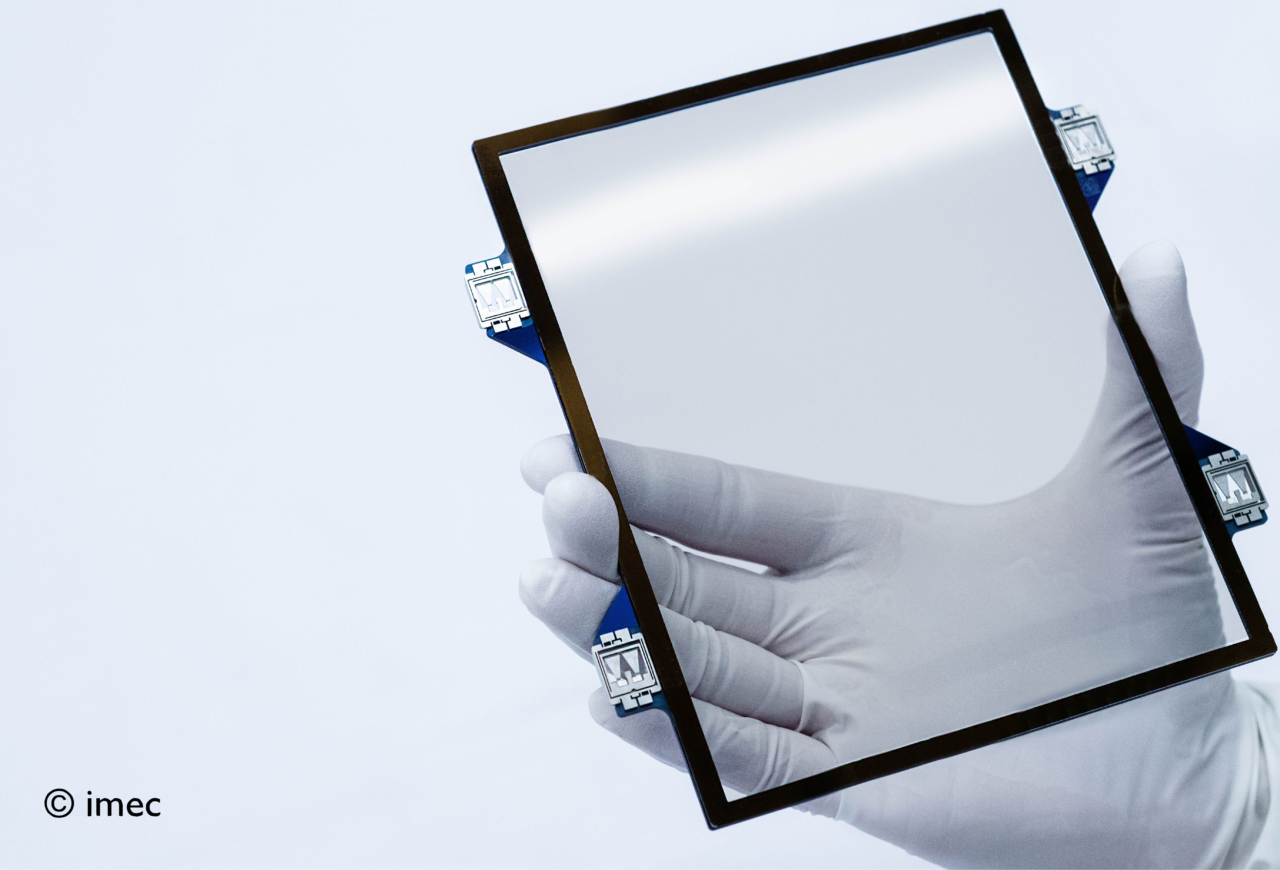

Imec demonstrates CNT pellicle use on EUV scanner

Since 2015, Canatu has been working with Imec to develop CNT pellicle membranes that meet targets for lifetime and properties such as transmittance, thermal durability, permeability, and strength.

Download technical paper

Please download the most recent 2023 SPIE Photomask + EUVL Conference proceedings to gain deeper understanding of our versatile platform technology, unique CNT synthesis and direct dry deposition benefits, common tailoring, and potential uses for our carbon nanotube membranes.

Download technical paper

CNT is a superior material for EUV pellicles

Fabricating a carbon nanotube membrane that is thin enough to limit the imaging impact while robust enough to survive handling is extremely challenging.

Firstly, the material must be highly transparent to the 13.5nm light that is absorbed by most materials. The higher the transmittance, the better the output, effectively lowering the cost per unit.

Canatu CNT pellicle membranes support productivity increase potential in the EUV lithography process by up to 7-15%.

Secondly, high transmission requirements must be met in order to support the trend towards increasing source power that results in higher temperatures. At 800W and above in the current scanner environment, other existing options begin to deteriorate.

High transmission and heat resistance aside, low flare is also required to print features with extreme precision without pattern distortion. Finally, EUV pellicles must meet stringent chemical and mechanical requirements to withstand the EUV scanner environment.

Carbon nanotubes are emerging as the most promising material for EUV pellicles used in the next-gen high-power scanners.

Since 2015, Canatu has collaborated with Imec, a world-leading research and innovation hub in nanoelectronics and digital technologies, to develop CNT-based EUV pellicles.

EUV pellicles were mounted on reticles and exposed in the NXE:3300 EUV scanner at Imec, demonstrating the successful fabrication and scanner handling of full-field CNT pellicles. The tested CNT pellicles had a single-pass EUV transmission up to 97%. The impact on imaging was found to be low and correctable.

Contact our specialist in CNT pellicle membranes

Send us a message

Related content

The next-gen EUV scanner will introduce high power levels of over 500W, enabling the next step in efficiency. Higher power levels and reticle acceleration cause high heat loads and mechanical stress on the EUV pellicles. Carbon nanotubes have emerged as the most promising material for EUV pellicles used in high power EUV scanners due to their mechanical and thermal properties. See article.

As EUV lithography becomes the norm for producing high-pitch patterning on wafers, the Canatu CNT will impact our everyday. “For me, that’s the true sign of carbon age”, said Ilkka Varjos, CTO of Canatu. Discover more.

Carbon nanotubes can be deposited on an open frame to form membranes of different densities. These membranes offer unique properties, unparalleled by any other material. Discover more.

Canatu CTO Ilkka Varjos presented free-standing CNT membrane platform technology at SPIE Photomask + EUVL 2021. His talk focused on the unique qualities of Canatu CNT, extensive customizability of the CNT synthesis and post-processing, and application potentials. See press release.

Canatu has the expertise to effectively adapt carbon nanotubes for different contexts and uses. The customizability and versatility of our synthesis process allows us to create the most advanced CNTs for highly engineered solutions. Discover CNT versatility.